Sproutdreamer

Member

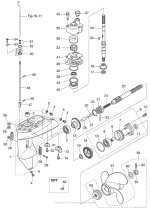

My 2012 MFS20 I thought had a gear change issue but turned out to be a mis-adjusted gear change cable. However having removed the engine from my boat I decided to check it over before selling the engine as I had then bought a bigger engine. On disasembling the lower leg just to have a look I found that despite the gear oil being pristrine, all the gears immaculate and gear oil having been changed every season there was noticable wear in the prop shaft outer needle and ball bearings. I have always treated the engine gently.

That is with only 400 hours of use (auxillary engine on a sailing cat) over 6 seasons ( I had a couple out). So new bearings and seals to replace before selling it on. Already previously replaced the engine power tilt switch and carburettor.

That is with only 400 hours of use (auxillary engine on a sailing cat) over 6 seasons ( I had a couple out). So new bearings and seals to replace before selling it on. Already previously replaced the engine power tilt switch and carburettor.