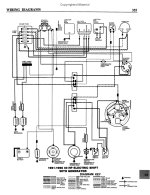

The voltage regulator on my 1965 40 hp Evinrude Lark VII selectric is missing. If the part is no longer available on Marineengine.com and I haven't found it elsewhere either. How can I determine the output voltage of the original part and use a newer part as a substitute? I don't see those properties in the wiring diagram(attached) that I found and I don't know how to work towards a solution. Any ideas?

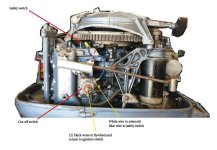

Also, how can I bypass the external electronics and just run the motor on a stand? I am working my way through cleaning and lubricating along with the tune up guidelines detailed in my 1975 Clymer service manual, but it doesn't detail bypassing the electronics for starting it in my situation. Any help would be appreciated.

Thank you in advance for any wisdom and knowledge you can pass on to a fledgling boat restorer.

Also, how can I bypass the external electronics and just run the motor on a stand? I am working my way through cleaning and lubricating along with the tune up guidelines detailed in my 1975 Clymer service manual, but it doesn't detail bypassing the electronics for starting it in my situation. Any help would be appreciated.

Thank you in advance for any wisdom and knowledge you can pass on to a fledgling boat restorer.