Hi Mark

The post got cut off some how, my apologies. My problem is that I installed an engine overheat alarm switch which triggers at 200 degrees to the left of the thermostat housing as viewed from the front of the motor.

If this over-heat alarm switch is installed in the intake manifold next to the OEM temp sender, and up-stream of the actual thermostat, I see no issues.

The motor runs at 140 Degrees at idle. While idling the temp switch is activating the alarm. Measuring the body of the temp switch with an Infra red temp gun it reads 192 degrees when it triggers which is ok.

A 200* alarm switch that is being triggered at 192* is probably not an issue. That's only an 8* differential.

The real question would be... "why is a 140* thermostat allowing for a 192* engine coolant temp in this area?"

The problem is that the factory temp sensor body located 8 inches away

in the same passage is reading a 138 degrees.

what I have here is a 55 degree temp difference over the span of the thermostat passage in the intake manifold.

That would be the coolant cross-over area, and is upstream of the actual thermostat location.

I thought perhaps the rebuilder may have installed the intake or head gaskets incorrectly possibly blocking a cooling passage.

My machinist says it's not possible on a SBC.

I would agree with him.

Any help would be greatly appreciated.

Questions:

.... Where the "spent" seawater leaves the H/E and enters the exhaust manifolds, are you using the correct brass or bronze 90* elbows with a smooth interior transition?

.... Are the two same area hoses in good condition?

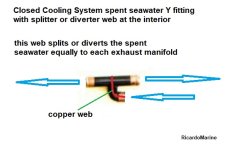

.... Is the Y fitting (that splits the spent seawater) equipped with the diverter web inside of it and is it in tact?

.... Are the gaskets (between the manifolds and elbows) fully open at the seawater transfer ports?

.... Are the gaskets (between the manifolds and elbows) fully open at the seawater transfer ports?

Example only