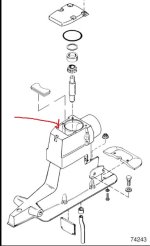

So I understand that the O-rings next to the U-joints are the 2 thinner ones. As far as the 3rd I assume the thicker is ok as per marineengine.com? It is a bit thicker but I think so is the groove.

As far as the grease I have Quicksilver marine grease 2-4-C w/PTFE, Mercury 2-4-C w/Teflon, Quicksilver High Performance SAE 90 gear lube. And I also have some other marine grease that I got with the 2 stroke jetskis and it's green in color, comes in a grease pump for trailer and other uses. I have some AMSOil Severe Gear SAE 75W-90 Pressure Lubricant. Used to have some other blue marine grease but cannot find it.

I don't have the special lubricant 101, or the Quicksilver engine Coupler Spline Grease.

In the book they mention the 2-4-c w/teflon and quicksilver high performance gearlube