The up/down switch is on the throttle lever by the instrument panel. I’m getting zero response from it and the easy problems like the fuse and and battery charge all check out fine. The connections on the switch look corroded and while the connections seem solid, I thought about buying a new switch but can’t find it anywhere. It sits in the top of the lever and is very small, so to disconnect the three wires I’d end up destroying the switch. The wires and connections in the switch are not touching each other so there’s no short there.

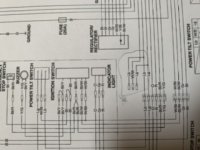

I don’t have a volt meter and am reluctant to delve into the relays, unless you think that’s absolutely necessary (I have the shop manual but the electrical stuff is a bit tricky for me.). Any thoughts on what I might be missing will be appreciated. Everything else - starter, lights etc work fine. Thanks.

I don’t have a volt meter and am reluctant to delve into the relays, unless you think that’s absolutely necessary (I have the shop manual but the electrical stuff is a bit tricky for me.). Any thoughts on what I might be missing will be appreciated. Everything else - starter, lights etc work fine. Thanks.