I stuck a long zip tie down the tube, plenty of grease in there, I pumped maybe a squeeze worth down there. Not sure what else other then tear it apart. Prolly not going to happen at this point. Unless there is another way to service it, without ripping it apart?

OK... first of all, if the PDS bearing service (i.e., greasing it) has been neglected, it will fail, and when it fails, the damage can be extensive.

Please take note!

That OEM fitting is a grease-cap style. You would fill the cap with grease, and as it's turned downwards, a cap full only of grease enters the system and reaches the bearings, but only if the grease cavity had been pre-filled during PDS assembly.

In short, it is very inefficient.

The fix:

The threads are 3/8" NC.

Remove the fitting and chase the 3/8" NC threads with a 1/8" Tapered Pipe tap.

DO NOT over tap...... run it in approx 2/3 of it's length!

Reach in and retrieve any aluminum debris (don't worry if you can't get it all).

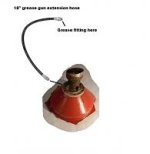

Now install an 18" grease gun extension hose with a zerk fitting in the end.

The hose will have 1/8" TP threads on each end.

Zip tie the loose end of the hose up near where it is easily accessible.

Once your new PDS bearing has been installed (and prior to installing the AFT most seal), pump the cavity full of grease until you see it exit the ball cage.

(the seal installs in the non-conventional direction)

Re-assemble the drive with NEW O-rings.

With the engine running, give it several more pumps of grease!

We took the boat out Saturday, ran and tootled around for a couple of hours. Drained the oil this morning, good news no water what so ever in the oil. Yea! But it was pretty dark albeit black for such a short trip. Again gonna have to live with it. Soot coming from somewhere, but I also read it does not take much to turn it black.

Compared to last year when running with just 2 people in the boat, it was running at 2900 to 3000 rpm's max and felt I wa stressing it. This last run with 2 people it was doing 3400 or so without seemingly pushing the engine.

If 3,400 RPM is your MAX, something is wrong. Perhaps incorrect propeller, dirty hull, incorrect drive ratio, etc!

Find out what it is before you damage your engine.