Ok guys, quick questions for you:

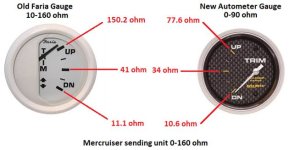

Trim gauge has an ohm rating of 0-90

Trim sending unit has an ohm rating of 10-160

Questions:

1. Will these two components be compatible with each other and work properly?

2. If these two components were connected to one another, how might the needle pointer on the trim gauge react?

Trim gauge has an ohm rating of 0-90

Trim sending unit has an ohm rating of 10-160

Questions:

1. Will these two components be compatible with each other and work properly?

2. If these two components were connected to one another, how might the needle pointer on the trim gauge react?