RicardoMarine

Gold Medal Contributor

All of this is relatively simple!

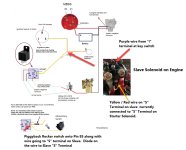

Your goals:

#1..... Find a way to operate the electric fuel pump once engine oil pressure is achieved.

#2..... Find a way to momentarily operate the electric fuel pump prior to engine oil pressure.

Option for #1:

N/O low oil pressure switch in the loop.

Options for #2:

Start by-pass circuit.

or

Momentary helm switch.

Questions:

I know that Mark and I do not agree on the use of a relay. However, consider this;

Do you want to place an additional 4 or 5 amp load directly on your ignition circuit?

(keep in mind the length of the engine harness/hull harness (from helm to engine location) the small size of this circuit (length = resistance) and that there is an engine harness/hull harness connector (also adding resistance) in the path.)

Do you want to use a relay and NOT have the additional 4 or 5 amp load directly on the ignition circuit?

(the current required to trigger a relay is extremely low)

If both the start-by-pass circuit and momentary helm switch circuit are used, a diode would be installed in the S circuit to avoid any back-feed that would activate the starter motor. In other words, you do not want the momentary helm switch to activate the S circuit while simultaneously triggering the relay.

That would defeat the purpose of the momentary helm switch function.

Take a look at my updated schematic.

Your goals:

#1..... Find a way to operate the electric fuel pump once engine oil pressure is achieved.

#2..... Find a way to momentarily operate the electric fuel pump prior to engine oil pressure.

Option for #1:

N/O low oil pressure switch in the loop.

Options for #2:

Start by-pass circuit.

or

Momentary helm switch.

Questions:

I know that Mark and I do not agree on the use of a relay. However, consider this;

Do you want to place an additional 4 or 5 amp load directly on your ignition circuit?

(keep in mind the length of the engine harness/hull harness (from helm to engine location) the small size of this circuit (length = resistance) and that there is an engine harness/hull harness connector (also adding resistance) in the path.)

Do you want to use a relay and NOT have the additional 4 or 5 amp load directly on the ignition circuit?

(the current required to trigger a relay is extremely low)

If both the start-by-pass circuit and momentary helm switch circuit are used, a diode would be installed in the S circuit to avoid any back-feed that would activate the starter motor. In other words, you do not want the momentary helm switch to activate the S circuit while simultaneously triggering the relay.

That would defeat the purpose of the momentary helm switch function.

Take a look at my updated schematic.

Last edited: