RicardoMarine

Gold Medal Contributor

I do have a vacuum gauge. I believe there is a plug on the side of manifold near the carb. Is that the best place to plug it in? Seems like the only place.

Yes..... that should work!

.

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.

I do have a vacuum gauge. I believe there is a plug on the side of manifold near the carb. Is that the best place to plug it in? Seems like the only place.

Temporarily install a vacuum gauge.

When adjusting the low speed mixture, shoot for the greatest vacuum reading.

You may need to simultaneously adjust the idle stop screw.

NOTE: the GM 3.0L in a Marine application is prone to what we call "run on" or "dieseling" upon shut down.

This is often caused by a lean air/fuel mixture and high cylinder temperature directly after a run.

You can address this later on!

The important aspect will be to see that this engine receives the correct ignition advance during the run-in period.

Be careful doing the idle mixture this way.

There are many factors that can influence this method.

please elaborate!

I would take the simplest path, do it by max rpm. results are the same but rpm is easier.

DISREGARD ADVANCE Spew........PCR doesn't understand the ignition system for this product.......If he did he wouldnt need to add this AGAIN TO ANOTHER THREAD!

Hale PCR!!

Sheesh..... childish and immature post count envy is once more present.

Okay I installed a new GM 3.0L in my 2001 Sea Ray 180 and everything is ready to go. It runs but I am a little unsure of where to set the timing. Do I go by the manual for the boat year or should I go by the Engine year?

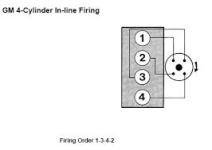

I may have found an issue. The specs listed for the new motor have the firing order 1,3,4,2. The Setec manual list it as 1,3,2,4. Sheesh how do I confirm this? Guess I just have to try it.

I pulled a couple plugs yesterday and they had some black soot so I did lean out the idle just a bit. I'm going to do a compression check and pull the dist and do some testing on it also. The new carb allowed it to stay running so I could set the timing but had no effect on the miss.I guess it is also possible a valve might need adjusting which would piss me off because it's supposed to be a brand new GM motor.

How much have you actually run this engine? 20 hours? 50? 2? Sooty plugs means that the main jets are too big. Idle mixture has nothing to do with it. All that does is keep it from stalling with the butterflys closed. Don't tune the engine at idle, as that has very little impact on overall performance.I pulled a couple plugs yesterday and they had some black soot so I did lean out the idle just a bit. I'm going to do a compression check and pull the dist and do some testing on it also. The new carb allowed it to stay running so I could set the timing but had no effect on the miss.I guess it is also possible a valve might need adjusting which would piss me off because it's supposed to be a brand new GM motor.