Walleye4Days

Contributing Member

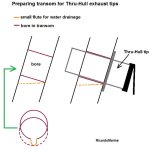

I'm trying to determine the best overall outlet dimension for my thru hull exhaust. I know that it's 3.75" (95mm) coming off of the risers, but meeting in the current y-pipe into one smaller outlet (for back pressure I'm assuming?)

So, do I run smaller exhaust sizes around 2.5" or so from each riser until exit, to keep some decent backpressure? Or, do I just run it straight through at 3.5" all the way out and rely on a muffler to create the back pressure needed?

I'm not the most versed on exhaust systems and the metrics of it all. So, just trying to get a good understanding of what's needed sizewise for the whole system. (It'll be dual exhaust when said and done, instead of meeting up with a y-pipe like current).

*The only reason I'm doing this is because when putting the exhaust bellow in place, the y-pipe outlet crumbled on 2 corner areas of the outlet, eliminating the bellow from being able to successfully be attached. (How this engine didn't blow up over the past 2 years with virtually no exhaust bellow is beyond me! Lol. But, I'm a lot more anal in the care of my boat VS previous owner, so I'm definitely fixing this unforeseen issue.)

**I didn't want to simply replace the y-pipe because I JUST got done pulling the engine, rebuilding the outdrive, and getting it all back together and the crumbling if this y-pipe was completely unforeseen/unplanned. If I can build a nice thru you'll exhaust without having to pull that engine again, I'd much rather take that route. At least, just to get through thru season until Nov 20th that is. In the winter time I'll go back through and really do it all out to basically a new boat again.

So, do I run smaller exhaust sizes around 2.5" or so from each riser until exit, to keep some decent backpressure? Or, do I just run it straight through at 3.5" all the way out and rely on a muffler to create the back pressure needed?

I'm not the most versed on exhaust systems and the metrics of it all. So, just trying to get a good understanding of what's needed sizewise for the whole system. (It'll be dual exhaust when said and done, instead of meeting up with a y-pipe like current).

*The only reason I'm doing this is because when putting the exhaust bellow in place, the y-pipe outlet crumbled on 2 corner areas of the outlet, eliminating the bellow from being able to successfully be attached. (How this engine didn't blow up over the past 2 years with virtually no exhaust bellow is beyond me! Lol. But, I'm a lot more anal in the care of my boat VS previous owner, so I'm definitely fixing this unforeseen issue.)

**I didn't want to simply replace the y-pipe because I JUST got done pulling the engine, rebuilding the outdrive, and getting it all back together and the crumbling if this y-pipe was completely unforeseen/unplanned. If I can build a nice thru you'll exhaust without having to pull that engine again, I'd much rather take that route. At least, just to get through thru season until Nov 20th that is. In the winter time I'll go back through and really do it all out to basically a new boat again.