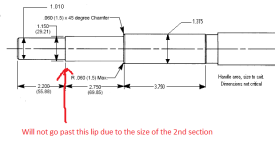

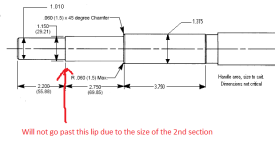

When aligning your engine should the alignment tool go all the way into the coupler? My tool only goes in the first two inches due to the size of the second stage of the tool. I could not locate a Volvo penta tool so I purchased a aftermarket brand. Is the first 2 inches all that is suppose to go into the coupler?

5.7 GI-E

DP-SM 1.95

TSX SX-M

5.7 GI-E

DP-SM 1.95

TSX SX-M

Last edited: