This post is a continuation of another post of mine - Yet Another Merc 40 2 Stoke 4 Cylinder won't idle http://www.marineengine.com/boat-fo...nother-Merc-40-2-Stroke-4-Cylinder-won-t-idle In that thread, the fellas on the forum determined that the carbs needed cleaned. I haven't done the carbs yet. I thought I would double check spark.

Now, a new problem. After many attempts, my '92 Merc 40 2 Stroke 4 Cylinder won't start or even bark. I was puzzled. I thought I would again verify I had spark. Used a Lisle 20610 spark tester and found I now have no spark on all 4 plugs. Tested the spark tester on my Kawasaki John Deere with electronic ignition and it gave off a nice orange spark.

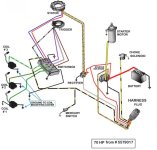

Any instructions of what to check upstream from the plugs? I have included pictures of my electrical panel. I have a multi-meter.

Now, a new problem. After many attempts, my '92 Merc 40 2 Stroke 4 Cylinder won't start or even bark. I was puzzled. I thought I would again verify I had spark. Used a Lisle 20610 spark tester and found I now have no spark on all 4 plugs. Tested the spark tester on my Kawasaki John Deere with electronic ignition and it gave off a nice orange spark.

Any instructions of what to check upstream from the plugs? I have included pictures of my electrical panel. I have a multi-meter.

Last edited: