Ok, I have the 171 running decent now, I'm ready to pull it from the donor boat and put it in my boat. From my understanding, I have to pull the out drive in order to get the engine out... correct?

Not necessarily. That typically applies to the gimbal suspension stern drives.

a..... if reusing the 131 flywheel cover (bell housing in the auto world), you can separate the engine from the flywheel cover, leaving the flywheel cover attached to the 275 transom shield.

b..... if pulling the 131 engine with the F/C attached to the engine, you will need to remove the transmission ONLY, and then carefully loosen the 6 clamping collar bolts.

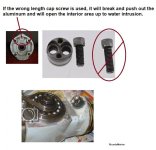

If doing "b" above, you will want to replace the inner most (forward) rubber cushion ring. Both rubber cushion rings provide the rear engine isolation, with the FWD rubber cushion ring providing the very important water seal.

Anyways, the 171 has a 290 behind it. The 131 I'm pulling out of my boat has a 275 behind it. Should I keep the 290 with the 171 or stay with the 275? Both of them are in decent shape and I believe they both operate properly.

The 290 will offer power trim..... the 275 will not.

If you take the 290 over to the keeper boat, you'll also need to take the trim pump and all wiring with it.

In either event, the final reduction needs to be 2.15:1.

Also should I keep the controls from the donor boat with the engine or am I ok with keeping the original controls in my boat?

If you take the 290 over to the keeper boat, you will want the trim control function to go with it.

Thanks in advance