Knowlzy0791

New member

Hey everyone,

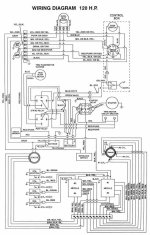

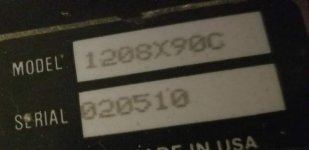

I have been working with a 1990 Force 120 for the past couple of weeks. I will get straight to the point.

Started with no power or anything. Have redone some wiring, rebuilt the fuel pump, rebuilt both carbs, replaced all spark plugs, verified spark at all cylinders, and pulled and cleaned all Reed valves. Also verified fuel makes it to both carb bowls through all fuel lines.

I check compression across all cylinders and got 150psi on all.

Engine now turns over, kind of sputters. Getting fuel to cylinders 3 and 4 but NOT to 1 and 2. I have swapped the carbs around, swapped floats, tried every combination I can think of and it is always the same outcome.

If I put starting fluid manually into the cylinders, or through the Reed valves, engine will fire immediately. Without that, only sputters on 3 and 4.

I have scoured these forums and Google. Called every marine mechanic around me. I am at a loss.

Any and all guidance would be greatly appreciated!

I have been working with a 1990 Force 120 for the past couple of weeks. I will get straight to the point.

Started with no power or anything. Have redone some wiring, rebuilt the fuel pump, rebuilt both carbs, replaced all spark plugs, verified spark at all cylinders, and pulled and cleaned all Reed valves. Also verified fuel makes it to both carb bowls through all fuel lines.

I check compression across all cylinders and got 150psi on all.

Engine now turns over, kind of sputters. Getting fuel to cylinders 3 and 4 but NOT to 1 and 2. I have swapped the carbs around, swapped floats, tried every combination I can think of and it is always the same outcome.

If I put starting fluid manually into the cylinders, or through the Reed valves, engine will fire immediately. Without that, only sputters on 3 and 4.

I have scoured these forums and Google. Called every marine mechanic around me. I am at a loss.

Any and all guidance would be greatly appreciated!

Last edited: