anothercarguy

New member

Hi All, New to the forum, though I've lurked many times and have read a number of threads over the past few years.

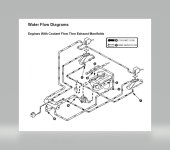

Details: 1990 22' Searay Sundancer, 260hp, 5.7 Mercruiser (Quadrajet carburetor), 750 hours, good compression), Alpha 1 Gen 1 leg, freshwater cooled, antifreeze runs through the manifolds, sea water through the risers, boat operated in Pacific Northwest salt water.

Symptom: as RPM's increase (specifically between about 2500-3500) the temp rises from about 165-170 to close to 200. If I stop the boat, put into neutral but increase engine rpm, temp comes down to 165-170 ish.

Work/solutions done to date:

I'm a car guy with a pretty well equipped shop, I build hot rods as a hobby so I'm comfortable working on engines and mechanicals. I'm obviously missing something here. Any thoughts out there?

Details: 1990 22' Searay Sundancer, 260hp, 5.7 Mercruiser (Quadrajet carburetor), 750 hours, good compression), Alpha 1 Gen 1 leg, freshwater cooled, antifreeze runs through the manifolds, sea water through the risers, boat operated in Pacific Northwest salt water.

Symptom: as RPM's increase (specifically between about 2500-3500) the temp rises from about 165-170 to close to 200. If I stop the boat, put into neutral but increase engine rpm, temp comes down to 165-170 ish.

Work/solutions done to date:

- ohmed out temperature sensor - within spec, tested gauge - tests full scale and 0 scale as it should

- replaced impellor in leg

- after looking into leg further replaced leg with new Sterndrive Engineering leg (issue with leg was not related to overheating, but it does come with yet another new impellor)

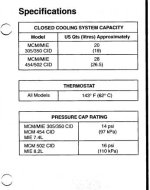

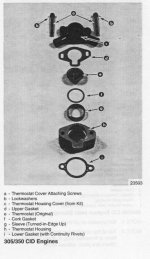

- tested engine thermostat in pot of warming water- opened fully as it should

- replaced transom seals and hoses - confirmed that sea water hose is not crimped/restricted

- checked hose from transom to power steering cooler, hose clear

- power steering cooler clear

- flow checked seawater pick up per the manual (don't recall specific numbers as this was done last year, but water flow characteristics were within manual specs at set RPM)

- rodded out heat exchanger - clear

- replaced engine water pump

- inspected manifolds and risers a couple times, looked fine... replaced them anyway with new Mercruiser units

- pulled heads, checked head gaskets, rebuilt and re-installed

- carb rebuilt - runs well (not lean, if anything, the plugs are a bit sooty)

- checked for any obstructions in all hoses, all are clear

- used infrared thermometer around engine, temps are slightly lower than the gauge indicates, but are close enough that I would say the gauge is indicating what is going on.

I'm a car guy with a pretty well equipped shop, I build hot rods as a hobby so I'm comfortable working on engines and mechanicals. I'm obviously missing something here. Any thoughts out there?