New to me, 350 hours each repower I did late last year. LA Fire Rescue engines, but they did sit for a couple of years without being run.

I've been fighting some issues where things got mis-adjusted, and some stuff just didn't work.

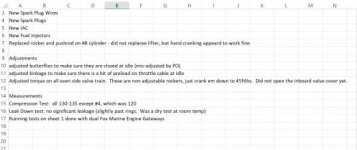

I did refresh most of the ignition just because it's been 20 years.

I'm still dogged by what is probably a miss, because the transmission is rattling at idle (not as bad as it used to), and I cannot get top end out of it.

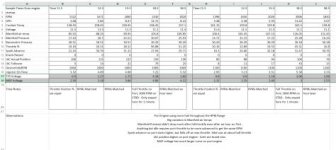

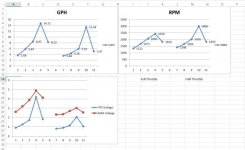

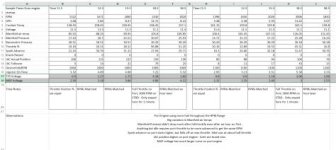

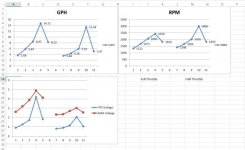

Since I have the technology, I did some samples of ECM parameters at various TPS and RPM settings to see if there's a glaring issue, or a pattern.

The results are attached as an Excel file. If you need it in another format, just ask.

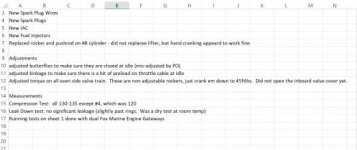

While you are looking at this, I am going to recheck fuel pressure compared with Starboard, and put another fresh set of plugs in it. There's a txt file of next stuff to try. The only mechanical thing I found so far was a valve rocker that had been punched thru by the lifter push rod, which was preventing the valve from opening much. I thought that was really going to be it, but I still can't top out in RPMs.

Ask away, I'm all ears.View attachment mercruiser ignition fuel tests.txt

View attachment mercruiser ignition fuel tests.txt

View attachment mercruiser ignition fuel tests.txt

I've been fighting some issues where things got mis-adjusted, and some stuff just didn't work.

I did refresh most of the ignition just because it's been 20 years.

I'm still dogged by what is probably a miss, because the transmission is rattling at idle (not as bad as it used to), and I cannot get top end out of it.

Since I have the technology, I did some samples of ECM parameters at various TPS and RPM settings to see if there's a glaring issue, or a pattern.

The results are attached as an Excel file. If you need it in another format, just ask.

While you are looking at this, I am going to recheck fuel pressure compared with Starboard, and put another fresh set of plugs in it. There's a txt file of next stuff to try. The only mechanical thing I found so far was a valve rocker that had been punched thru by the lifter push rod, which was preventing the valve from opening much. I thought that was really going to be it, but I still can't top out in RPMs.

Ask away, I'm all ears.View attachment mercruiser ignition fuel tests.txt

View attachment mercruiser ignition fuel tests.txt

View attachment mercruiser ignition fuel tests.txt