Crumbliss.r639

New member

Greetings everyone,

For starters I am actually not new to The Forum however I I just finally made an account. I have been trolling the forums and getting the information I need for a few weeks now. I bought a Bayliner recently for $150. The motor cranks but would not run the interior is trashed but the transom is sound and the hull is good.

After a couple weeks worth of work I have the engine running, the outdrive runs great, the seawater system is working without leaks, the outdrive lift is functioning properlyb everything on the Boat Works. Thank you all for the help that you didn't know you were giving me.

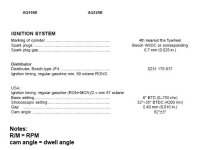

Now for my problem. The boat runs and idles like a dream however every time I move the boat with the truck it seems like the distributor jumps a gear. This is easily remedied I simply pull the distributor move the tooth back 1 and it fires right up. The timing belt is very loose between the cam and the pulley that runs the distributor. The tensioner is keeping tension between the cam and the crank but it's not pulling the tension on the other side. When I was working on the boat the reason it wouldn't run is because the timing was not even remotely close to correct with the cam at top dead center number one the crank was about 40 degrees off and the other shaft was about a hundred and twenty degrees off. So I purchased a new belt I cleaned the pulleys with a wire wheel they weren't Rusty so I just cleaned them up and reused the same pulleys.

So before I take the front end of the engine off again my question is should there be Slack on that side or am I needing to shift the slack to between the cam and the crank so that the tensioner can absorb it?

For starters I am actually not new to The Forum however I I just finally made an account. I have been trolling the forums and getting the information I need for a few weeks now. I bought a Bayliner recently for $150. The motor cranks but would not run the interior is trashed but the transom is sound and the hull is good.

After a couple weeks worth of work I have the engine running, the outdrive runs great, the seawater system is working without leaks, the outdrive lift is functioning properlyb everything on the Boat Works. Thank you all for the help that you didn't know you were giving me.

Now for my problem. The boat runs and idles like a dream however every time I move the boat with the truck it seems like the distributor jumps a gear. This is easily remedied I simply pull the distributor move the tooth back 1 and it fires right up. The timing belt is very loose between the cam and the pulley that runs the distributor. The tensioner is keeping tension between the cam and the crank but it's not pulling the tension on the other side. When I was working on the boat the reason it wouldn't run is because the timing was not even remotely close to correct with the cam at top dead center number one the crank was about 40 degrees off and the other shaft was about a hundred and twenty degrees off. So I purchased a new belt I cleaned the pulleys with a wire wheel they weren't Rusty so I just cleaned them up and reused the same pulleys.

So before I take the front end of the engine off again my question is should there be Slack on that side or am I needing to shift the slack to between the cam and the crank so that the tensioner can absorb it?