Christiaan

New member

Hello,115 mercury from 1993 is having a problem with its powertrim.

So now and then the relays keep sticking, so the engine keeps going up/or down after letting the trimbutton go. Not always, but especially when it draws high current (like when i trim up, when i am going with a bit of speed).

I understand that the current is to high, and that that is the reason that the contacts in the relay melts, and keeps sticking. But why is the current to high? What can be damaged that is making the current so high?

By the way, i am not talking about the solenoids. Those seem fine.

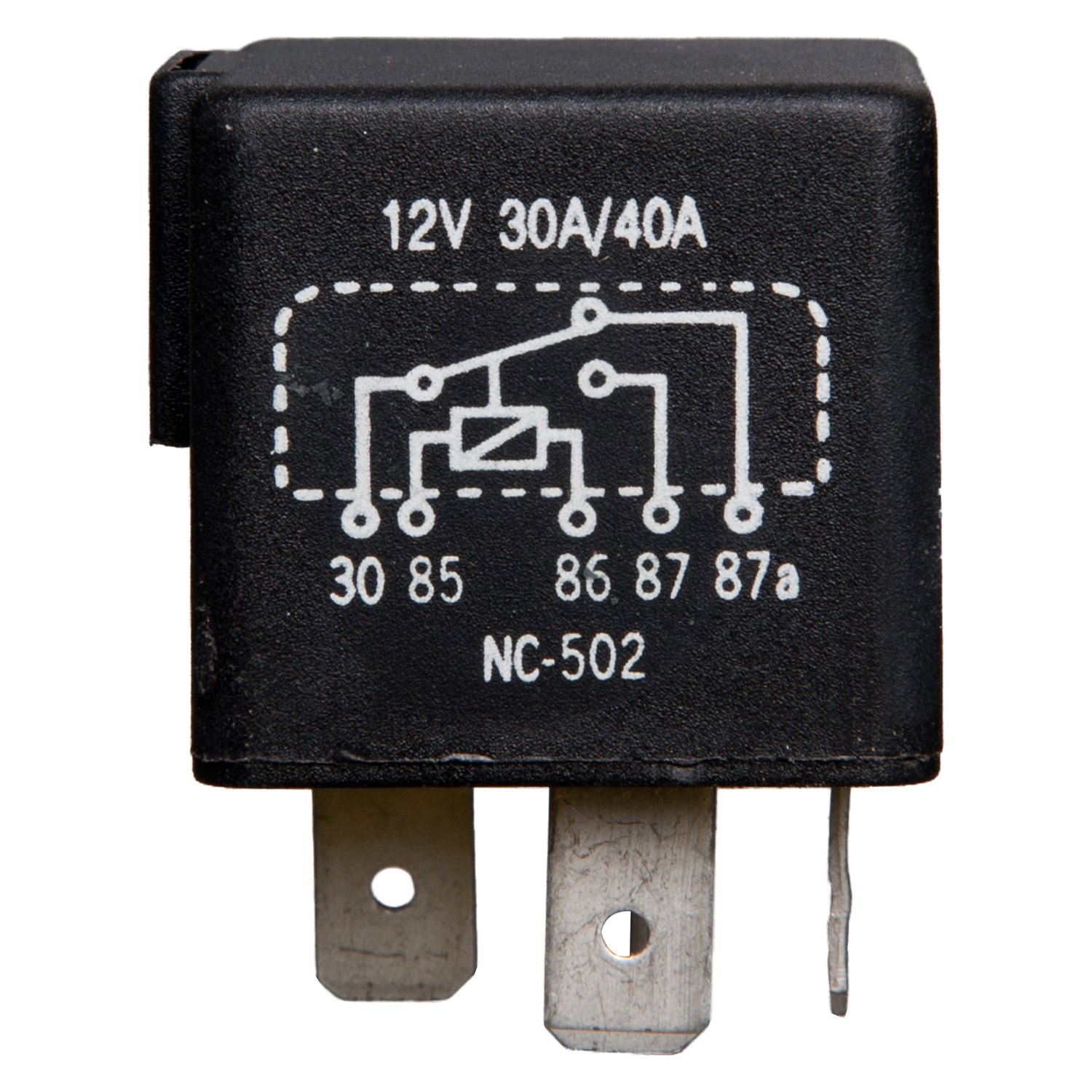

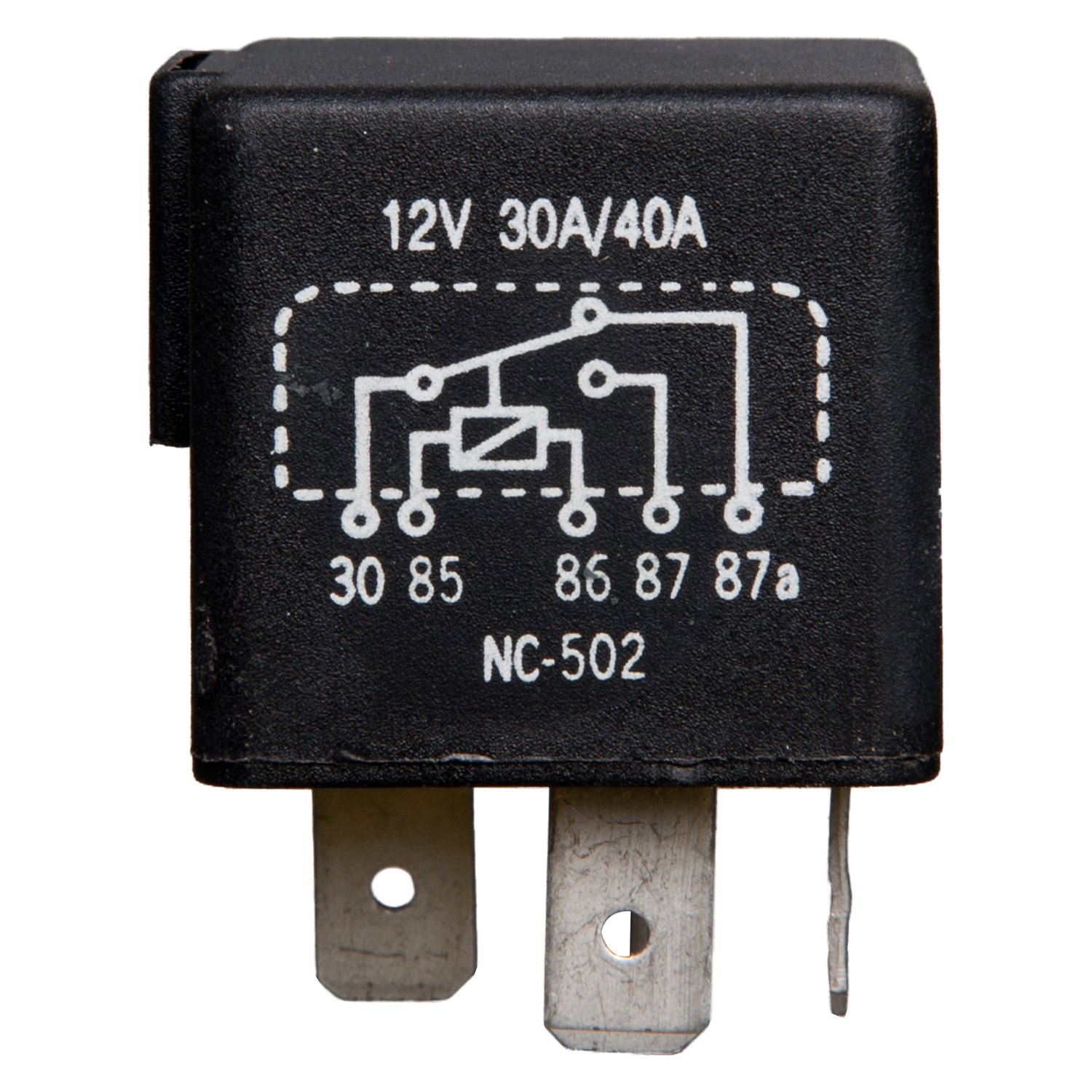

The relays are:

My 115 HP mer

So now and then the relays keep sticking, so the engine keeps going up/or down after letting the trimbutton go. Not always, but especially when it draws high current (like when i trim up, when i am going with a bit of speed).

I understand that the current is to high, and that that is the reason that the contacts in the relay melts, and keeps sticking. But why is the current to high? What can be damaged that is making the current so high?

By the way, i am not talking about the solenoids. Those seem fine.

The relays are:

My 115 HP mer