Colinkris1

Member

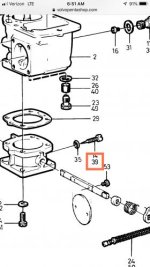

Hi - New to forum and new owner of 1992 Glastron G1900 with Volvo Penta 250A. Boat hasn’t seen water since 2010. I had to replace battery, starter, wires, and points. I also had to pump out 12 gallons of 9 year old gas. I dropped nose of trailer with it backed up a hill. Removed fuel sender and pumped ALL old fuel out. I removed anti siphon fitting from fuel line end of tank, but could not unthread the 90 degree fitting from the metal bushing in plastic tank to get the pick up hose strainer out. I Had to satisfy myself with spraying carb cleaner down pickup hose to tank strainer immediately followed by a gallon of gas and then compressed air. Drained all that out too and put anti siphon fitting back with NEW fuel line and filter to fuel pump inlet. I took the twin Solex carbs off and apart spraying all the orifices and blowing out with compressed air. I just wanted to hear it run (no raps or knocks) before spending money on carb kits. It ran fine for a few mins then started loading up. The tops come off pretty easily and I could see the bowl of carb closer to the front was nearly overflowing whereas the rear bowl was about half full. I pulled both floats, but neither felt like it had fuel in it. I swapped their locations to see if trouble followed the float but before I even put back together noticed front needle/seat had debris in it (holding needle open a bit). I cleaned it out and reassembled. This is a 1992 (I believe last year of the 250A) and my idle air needles are different from the early ones. Mine have a narrow head that recesses into the carb base and my setting is 8 turns out from stop. Anyway put back together and ran ok if a little rich but not much change with idle air screw adjustments followed shortly thereafter with loading up again (could see fuel water falling down center jet in Venturi). I tried cleaning needle again (more debris) and had same results. At this point I ordered kits. The two carbs have banjo bolt connections on one steel line down to fuel pump. I pulled that line and both carbs. Disassembled completely and soaked for max time of four hours steel line and banjo bolts too! While that was soaking, I pumped seafoam into fuel pump and let that soak as well. Four hours later I pumped gas into fuel pump forcing seafoam out. I sprayed out all orifices in carbs (after soaking) and blew through with compressed air. Reassembled with new parts from kits except idle air valve as was incorrect part for my later model 44PA1 carbs. No more crud ! Right? Made initial adjustments to idle stop screws and air needles. Started right up. Idled 900 RPM . No loading up running on water ears for 15 minutes varying RPMS. Throttled right up and dropped down to idle smooth. Only issue was idle air screw didn’t seem to make drastic difference unless I turned in two or more turns (from 8 out) - then it would start to choke out a bit. Cranking out from 8 didn’t seem to change really though I didn’t fiddle much because it would idle at 900 with the 8 turns out starting point. Next day test on the lake. Put in the water and test drive for like 10-15 mins. Throttled down to sit a minute and it stalled out. It didn’t take me long to realize I was loading up again. With control set to throttle only I had to ramp up to like 1500-2000 RPM immediately or it would stall out. I tried driving around for a while but same result at idle it would stall. Not fun putting back on trailer and in NH this time of year you REALLY DON’T WANT TO GET YOUR FEET WET! Anyway, what am I missing here? I plan to pull off flame arrestors and run on water ears to see if it’s the same carb loading up. If so, THERE HAD BETTER NOT STILL BE DBRIS GETTING IN NEEDLE AND SEAT! Some folks mentioned Ethanol crud clogging beyond what carb cleaner can remove (they used wire). I certainly could be a victim of that with 9 year old fuel. So I have a couple of questions. Looking at the carbs as mounted on the manifold. The side facing away from the engine has the MAIN jet behind a brass plug (on the side of the carb facing me). Which jet is the one on the top center of Venturi (the one with the long tube attached). I assume the low/idle jet is on the side of the very bottom near the throttle plate below the main jet plug. Also, what is the jet looking thing on the right hand side of the carb by the Venturi lock screw? I did look at some of this in a 1991 Sealoc manual and may just be forgetting some of this, but my 1992 is different slightly because the idle air screws themselves and the number of turns out from seated are drastically different from the 1991 in the book. All else is the same. Help! I don’t mind taking apart again and investigating, but I DON’T want to reassemble have it run mint at home and then crap out on the lake again. Thanks for being patient reading all of this and thanks in advance for any advice.