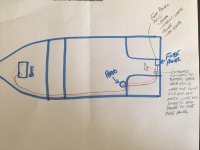

On my hunting boat, I have a 1998 Honda BF40 tiller. I have a Perko switch wired to a single battery, which is really just acting as a master shut off switch right now. From the Perko, it has a hot wire that powers an external fuse panel that has my lights, bildge, and graph connected to it. It also connects off to the engine for the starter.

I have two scenarios that will turn off my graph when using the engine.

1.) Upon a cold start up, it will turn off the graph if powered on before. Once warm it does not shut if off 100% of the time.

2.) Sometimes, when moving to top end speed it will shut off the graph. Either when I go from idle to max throttle or when operating at full throttle. It does not do it 100% of the time.

To me it is like my engine is drawing too much, which causes the graph to not get the required juice. The graph will turn back on if I power it up again with the engine running.

I prefer to not add a second battery, any suggestions on how to potentially solve this? I know electrical is a hard topic to digest without a graphic, I will try to make one if needed.

Thanks,

Eric

I have two scenarios that will turn off my graph when using the engine.

1.) Upon a cold start up, it will turn off the graph if powered on before. Once warm it does not shut if off 100% of the time.

2.) Sometimes, when moving to top end speed it will shut off the graph. Either when I go from idle to max throttle or when operating at full throttle. It does not do it 100% of the time.

To me it is like my engine is drawing too much, which causes the graph to not get the required juice. The graph will turn back on if I power it up again with the engine running.

I prefer to not add a second battery, any suggestions on how to potentially solve this? I know electrical is a hard topic to digest without a graphic, I will try to make one if needed.

Thanks,

Eric