I'm trying to finish my friend's 1990 70hp 3 cylinder so he can sell the boat, and I have run into a problem with the Idle Speed and Synch and Link adjustments, here it is:

On the water, I had to set the idle speed at the maximum the idle speed adjustment screw would go in, in order to get the RPMs the engine needed to not keep turning off at idle when starting in cold. To be more detailed, every time when I would turn off the engine to fish for say 15 minutes, I would have to rev it up, accelerating in neutral to get the engine to start, it would not start at the idle speed. With the idle adjustment screw all the way, it worked better, but still not really good like I've experienced in the other engines that I have had or worked on in the last 7 years. Those engines in the same situation, turned on just by touching the key without any acceleration in neutral, just in idle speed.

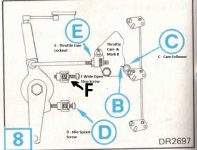

After I set the Idle Speed Screw to the maximum, the engine idle speed in neutral was 1275 to 1300+ rpm on my hand held tach, but in gear it was around 800+, which worked fine. Later when I went to set the Throttle Cam Mark (B) to the Cam Follower (C) they would not align until I set the Throttle Cam Locknut (E) to the maximum it would screw into the left. Then in order to get the Wide Open Throttle, I had to set the Wide Open Stop Screw (F) all the way out so the stop was actually the body of the engine, not the screw. In other words, In order to get the Cam Mark to align, I had to set the Idle Stop Screw to the maximum it will go in, the Wide Open Stop to the Maximum it will go out, and the throttle cam follower screw to the maximum it will go back to the left, everything is maxed out!

I had previously set the carburetor idle mixture needles at one turn out, which improved the rpms. I had adjusted the carb throttle plate. The engine runs great at high speed.

On the water, I had to set the idle speed at the maximum the idle speed adjustment screw would go in, in order to get the RPMs the engine needed to not keep turning off at idle when starting in cold. To be more detailed, every time when I would turn off the engine to fish for say 15 minutes, I would have to rev it up, accelerating in neutral to get the engine to start, it would not start at the idle speed. With the idle adjustment screw all the way, it worked better, but still not really good like I've experienced in the other engines that I have had or worked on in the last 7 years. Those engines in the same situation, turned on just by touching the key without any acceleration in neutral, just in idle speed.

After I set the Idle Speed Screw to the maximum, the engine idle speed in neutral was 1275 to 1300+ rpm on my hand held tach, but in gear it was around 800+, which worked fine. Later when I went to set the Throttle Cam Mark (B) to the Cam Follower (C) they would not align until I set the Throttle Cam Locknut (E) to the maximum it would screw into the left. Then in order to get the Wide Open Throttle, I had to set the Wide Open Stop Screw (F) all the way out so the stop was actually the body of the engine, not the screw. In other words, In order to get the Cam Mark to align, I had to set the Idle Stop Screw to the maximum it will go in, the Wide Open Stop to the Maximum it will go out, and the throttle cam follower screw to the maximum it will go back to the left, everything is maxed out!

I had previously set the carburetor idle mixture needles at one turn out, which improved the rpms. I had adjusted the carb throttle plate. The engine runs great at high speed.

What could cause the idle to have to be set the maximum, and really still not work right? Dirty carb? Electrical?

(P.S.- I had not run the engine for 2 months, and the other day when I went to turn it on, it revd at 2000 rpms in neutral and I could not get it to go down to the normal 1300, so maybe whatever is slowing it down was cleared, because the way the idle speed screw is set, it should be reving at 2000. Yesterday when I went to check the problem, once again it was at 1300 rpms.)

(P.S.- I had not run the engine for 2 months, and the other day when I went to turn it on, it revd at 2000 rpms in neutral and I could not get it to go down to the normal 1300, so maybe whatever is slowing it down was cleared, because the way the idle speed screw is set, it should be reving at 2000. Yesterday when I went to check the problem, once again it was at 1300 rpms.)

Last edited: