s2sailorlis

Member

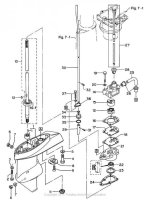

Have a 1994ish M5B ULS.

Noticed when I drained oil in late early December it looked like this the attached. Note that it has been in the jar since December 5th or thereabouts.

It doesn't appear the "milky white" - but it didn't come out clean either...assuming this is water infiltration. NOTE: The area of "dark green" is slowly getting thicker relative to the lighter green area. It was originally about 25% of the current thickness when I drained the lower unit. Also, when I drained the unit I did not notice any water initially draining from the bottom.

So, with my Pressure/Vaccum test mightyvac...I tested at 8 inches HG - vacuum and pressure. It held vacuum for at least 30 minutes, then I release vacuum. When I pressure test, I notice some bubbling from the white seal that the shifter rod goes thru. But pressure loss was minimal.

Also pressure tested in a large bucket - no bubbles coming from prop shaft seal, or drive shaft area (although I didn't remove the impeller housing yet). I did see bubbles from the shift rod area.

The shift rod seal is only 3 years old as I installed a new water pump, drive shaft seal, and every other part associated with the pump and housing..(not just the impeller.). And of course I put new washers on the fill and level screws every year.

And yes I have a Factory and 3rd party repair manual.

Thoughts appreciated. Thanks in advance.

Noticed when I drained oil in late early December it looked like this the attached. Note that it has been in the jar since December 5th or thereabouts.

It doesn't appear the "milky white" - but it didn't come out clean either...assuming this is water infiltration. NOTE: The area of "dark green" is slowly getting thicker relative to the lighter green area. It was originally about 25% of the current thickness when I drained the lower unit. Also, when I drained the unit I did not notice any water initially draining from the bottom.

So, with my Pressure/Vaccum test mightyvac...I tested at 8 inches HG - vacuum and pressure. It held vacuum for at least 30 minutes, then I release vacuum. When I pressure test, I notice some bubbling from the white seal that the shifter rod goes thru. But pressure loss was minimal.

Also pressure tested in a large bucket - no bubbles coming from prop shaft seal, or drive shaft area (although I didn't remove the impeller housing yet). I did see bubbles from the shift rod area.

The shift rod seal is only 3 years old as I installed a new water pump, drive shaft seal, and every other part associated with the pump and housing..(not just the impeller.). And of course I put new washers on the fill and level screws every year.

And yes I have a Factory and 3rd party repair manual.

Thoughts appreciated. Thanks in advance.

Attachments

Last edited: