edward.2525

Member

Laying the wire out on plywood is a great idea.

My wiring harness is in terrible shape.

New wires have been soldered to the ones left.

The wiring harness that goes to the front of the boat is in good shape.

The part going to the motor is not, and is the part that had wires soldered.

I thought that I could figure out which wire matches to which.

Can not.

There is not any color left the most of the wires.

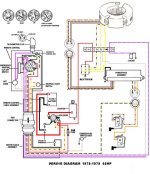

Looking at the wiring diagram, I see that it is not possible to just pick a wire and use it.

There is a path that has to be followed.

I think that the only way that I am going to be able to finish the wiring is to do what you have done.

I am not sure about using automotive wire. I guess the wiring could be checked every now and then.

I think that as this wiring is figured out, I will compare the cost of the two types of wiring.

I don't think that marine wire would cost that much more. We'll see.

Thank you all for the information.

Ed

My wiring harness is in terrible shape.

New wires have been soldered to the ones left.

The wiring harness that goes to the front of the boat is in good shape.

The part going to the motor is not, and is the part that had wires soldered.

I thought that I could figure out which wire matches to which.

Can not.

There is not any color left the most of the wires.

Looking at the wiring diagram, I see that it is not possible to just pick a wire and use it.

There is a path that has to be followed.

I think that the only way that I am going to be able to finish the wiring is to do what you have done.

I am not sure about using automotive wire. I guess the wiring could be checked every now and then.

I think that as this wiring is figured out, I will compare the cost of the two types of wiring.

I don't think that marine wire would cost that much more. We'll see.

Thank you all for the information.

Ed