Many years back (1968) OMC made a choice to change wiring suppliers (due to cost of course) which turned out to be a huge mistake as the insulation portion of the wires was inferior, cracked and fell away in just a couple years or so, leaving bare wires throughout their entirety.

OMC realized their error and corrected it by backtracking to a superior wiring supplier.... however it was just too late for the engines already equipped with the cut rate junk wiring.

As time went by, eventually the wiring harnesses became Non Available, and through my 30+ years of experience, I encountered a few boaters who apparently loved their 1968 engines... BUT... the wiring harnesses created a first class fire trap. The cure was time consuming and perhaps listed as expensive to some, however on three occasions what I did for the customers, as requested, follows:

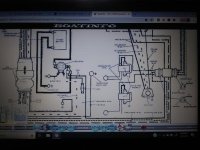

A piece of 1/4" plywood, large enough to lay out the entire engine wiring harness in its original shape became my bench top.

The wiring harness was carefully removed from the engine and painstakingly laid on top of the 1/4" plywood sheet, carefully arranging it to follow the engine's curvatures and electrical taped routes.

Finishing nails were applied on both sides of the harness wires so as to keep them in place while working on restoring it. Whatever electrical tape remained, it was then removed.

Each wire was now replaced, one by one, by a same gauge identical color coded wire, with the identical terminals soldered on its ends as equipped by the factory. I always added 1" of wire to be on the safe side... better too long than to be too short!

Eventually all wires of the proper color and gauge were replaced, new terminals installed, and most important... the routing was identical as it should be (No Mickey Mouse patch work). All that was left was to apply electrical tape to keep it all together before removing it from the nail studded sheet of plywood.

Time consuming?... You betcha! Expensive?... Beats buying a new engine due to a bad wire!

Would I do it again now, at my age?.... Not on your life!