This spring I purchased a 1997 Cruisers 35' boat with twin Mercruiser 7.4L (454) carbureted engines, FWC full closed cooling system with inboards and 625 hrs. I had the engines surveyed prior to the purchase and was told both engines had bad cylinder compression due to water intrusion and required top end engine rebuilds.

I bought the boat at a reduced price and immediately had all the work performed by a Certified Mercruiser Mechanic. When work was finished, I made my maiden voyage to my marina located in the Upper Chesapeake 2 hours away.

Work performed as described by mechanic

• Resurfaced heads

• Reconditioned values

• Installed new head gaskets

• Installed new Mercruiser exhaust manifolds, risers and elbows.

Problem: Even though the engines run good, I’ve been chasing a slow coolant leak in both engines for the entire season. This coolant leak requires me to add 4 - 8 oz coolant in both engines every time I take the boat out. The coolant leak does not appear to be going into the engine’s oil or the boat’s bilge and my thoughts are it's going out the exhaust.

The mechanic has not been responsive to my requests to look at this issue. I've now taken it upon myself find the source of the coolant leak. I've been performing a battery of tests along with removing and replacing parts but still can’t identify the root cause.

Here's everything I’ve done so far

• Installed new heat exchangers and pressure (radiator) caps on both engines

– No impact

• Performed cooling system pressure test

– Both engines held at 16 psi

• Performed cylinder compression test

– Starboard engine 130-135 psi all cylinders

– Port engine 130-140 psi all cylinders

• Performed cylinder leak-down test (75 psi input)

– Starboard engine 5%-10%, except cylinder 4 was 20%

– Port engine 4%-12% all cylinders

• Put UV dye in coolant system in both engines

– No leaks detected

• Checked for combustion gases released into coolant with a chemical block tester

– No gases detected on either engine

• Engine oil was analyzed at end of season (25 hrs logged on engines)

– Sodium level 29 ppm on Starboard engine

– Sodium level 56 ppm on Port engine

• Performed pressure test on exhaust manifold and riser isolated from boat's cooling system

– Starboard engine's manifolds and risers held at 20 psi

– Port engine’s manifolds have not been removed and tested yet

Observations

• Both engines run good but produce white smoke.

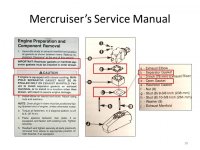

• Mechanic put the block off gaskets between risers and elbows and re-plumbed the coolant hoses to the riser fittings.

– Mercruiser's service manual specifies the block off gaskets MUST go between the manifold and riser

• When starting the engines cold with the heat exchanger’s pressure caps off....

– Coolant pushes out of the heat exchangers in 60 seconds

• When checking for combustion gases in the coolant with heat exchanger's pressure caps off and funnel attached....

– I noticed small bubbles (non-violate) when revving the engines. Bubbles in port engine were a little more noticeable.

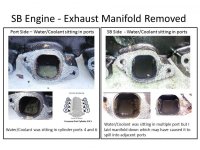

• All 4 exhaust manifolds have water/coolant sitting in the bottom of the manifold port chambers.

– Starboard engine's manifolds were removed,inspected & tested. I couldn't find obvious signs of a gasket failure.

– Port engine's manifolds still installed on engine but I can see water sitting inside with my borescope camera

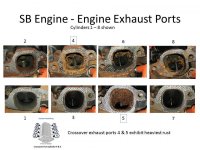

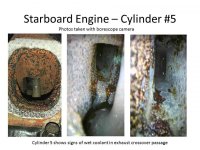

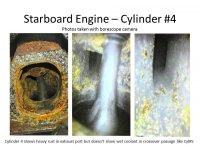

• Starboard engine's exhaust port openings show signs of moisture and rust

– Excessive rust detected in the exhaust port openings at the exhaust crossover ports at Cylinders 4 and 5

Things left to try

• Remove port engine's exhaust manifolds to look for signs of gasket failure, rust and moisture in ports.

• Remove heads and intake manifolds to look for signs of leaks. *LAST RESORT*

Question: Does anyone have advice or personal experiences they could offer in my quest to find this coolant leak in both engines?

I bought the boat at a reduced price and immediately had all the work performed by a Certified Mercruiser Mechanic. When work was finished, I made my maiden voyage to my marina located in the Upper Chesapeake 2 hours away.

Work performed as described by mechanic

• Resurfaced heads

• Reconditioned values

• Installed new head gaskets

• Installed new Mercruiser exhaust manifolds, risers and elbows.

Problem: Even though the engines run good, I’ve been chasing a slow coolant leak in both engines for the entire season. This coolant leak requires me to add 4 - 8 oz coolant in both engines every time I take the boat out. The coolant leak does not appear to be going into the engine’s oil or the boat’s bilge and my thoughts are it's going out the exhaust.

The mechanic has not been responsive to my requests to look at this issue. I've now taken it upon myself find the source of the coolant leak. I've been performing a battery of tests along with removing and replacing parts but still can’t identify the root cause.

Here's everything I’ve done so far

• Installed new heat exchangers and pressure (radiator) caps on both engines

– No impact

• Performed cooling system pressure test

– Both engines held at 16 psi

• Performed cylinder compression test

– Starboard engine 130-135 psi all cylinders

– Port engine 130-140 psi all cylinders

• Performed cylinder leak-down test (75 psi input)

– Starboard engine 5%-10%, except cylinder 4 was 20%

– Port engine 4%-12% all cylinders

• Put UV dye in coolant system in both engines

– No leaks detected

• Checked for combustion gases released into coolant with a chemical block tester

– No gases detected on either engine

• Engine oil was analyzed at end of season (25 hrs logged on engines)

– Sodium level 29 ppm on Starboard engine

– Sodium level 56 ppm on Port engine

• Performed pressure test on exhaust manifold and riser isolated from boat's cooling system

– Starboard engine's manifolds and risers held at 20 psi

– Port engine’s manifolds have not been removed and tested yet

Observations

• Both engines run good but produce white smoke.

• Mechanic put the block off gaskets between risers and elbows and re-plumbed the coolant hoses to the riser fittings.

– Mercruiser's service manual specifies the block off gaskets MUST go between the manifold and riser

• When starting the engines cold with the heat exchanger’s pressure caps off....

– Coolant pushes out of the heat exchangers in 60 seconds

• When checking for combustion gases in the coolant with heat exchanger's pressure caps off and funnel attached....

– I noticed small bubbles (non-violate) when revving the engines. Bubbles in port engine were a little more noticeable.

• All 4 exhaust manifolds have water/coolant sitting in the bottom of the manifold port chambers.

– Starboard engine's manifolds were removed,inspected & tested. I couldn't find obvious signs of a gasket failure.

– Port engine's manifolds still installed on engine but I can see water sitting inside with my borescope camera

• Starboard engine's exhaust port openings show signs of moisture and rust

– Excessive rust detected in the exhaust port openings at the exhaust crossover ports at Cylinders 4 and 5

Things left to try

• Remove port engine's exhaust manifolds to look for signs of gasket failure, rust and moisture in ports.

• Remove heads and intake manifolds to look for signs of leaks. *LAST RESORT*

Question: Does anyone have advice or personal experiences they could offer in my quest to find this coolant leak in both engines?