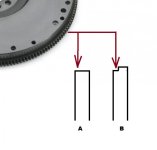

Good morning all! I had my port motor in my 38-ft carver blow back in July. Ordered a rebuilt GenIV, but they ended up sending me a Service Replacement (Gen VI with fuel pump boss). The flywheel and harmonic balancer are not the same. have a brand new balancer on the way, but been struggling with the flywheel. Finally bought one off of Ebay for a GenV/VI and it arrived yesterday. Just occurred to me that it is most likely for a sterndrive though. Part number is 10101171. I have heard of people removing the 168-tooth ring, heating it and installing on the other side of the flywheel. How difficult is this? Is a 10101171 for a sterndrive? Or inboard? Hard to find info. Thanks!

Home

Outboard Motor Parts

Chrysler outboard parts Evinrude outboard parts Force outboard parts Honda outboard parts Johnson outboard parts Mariner outboard parts Mercury outboard parts Suzuki outboard parts Tohatsu outboard parts Yamaha outboard partsInboard & Sterndrive Engine Parts

Chrysler Marine inboard parts Crusader Marine parts MerCruiser sterndrive parts OMC sterndrive parts Pleasurecraft Marine parts Volvo Penta marine parts + MoreAll Engine Brands

All Manuals HomeOutboard Repair Manuals

Chrysler outboard manuals Evinrude outboard manuals Force outboard manuals Honda outboard manuals Johnson outboard manuals Mariner outboard manualsMercury outboard manuals Nissan outboard manuals Suzuki outboard manuals Tohatsu outboard manuals Yamaha outboard manuals

Inboard & Sterndrive Engine Manuals

MerCruiser sterndrive manuals OMC sterndrive manuals Volvo Penta marine engine manualsPlease Note

MarineEngine.com does not offer troubleshooting assistance or repair advice by email or by telephone.

You are invited to join our public Boat Repair Forum to seek assistance from other members.

You may also visit the Boat Motor Manuals section of our site to obtain a service manual.