My 1986 Sea Ray 390 Express has Crusader 454s with the standard belt driven Sherwood sea water pumps. They are a PITA to adjust the belts and it's time to remove and rebuild them this winter. Thinking of taking the opportunity to convert to the crank mounted pumps instead. My concern is there is only about 6 inches between the front of the harmonic balancer and the bulkhead. I believe the Sherwood P110 pump is 4" from the mounting flange the end of the impeller cover screws. Of course that would only leave about 2" clearance for impeller changes and installation/removal.

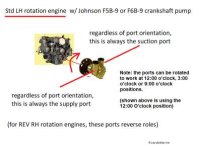

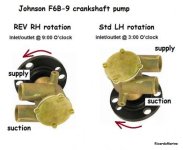

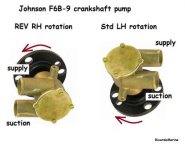

Is this installation feasible? Is the P110 the right pump? The P110 has the inlet/outlet connections at 180 degrees and the hose install seems problematic. I think there are other pumps from Sherwood or Johnson with the ports in the vertical position that would make the hose installation much easier. Anyone make a similar installation and have any recommendations.

Is this installation feasible? Is the P110 the right pump? The P110 has the inlet/outlet connections at 180 degrees and the hose install seems problematic. I think there are other pumps from Sherwood or Johnson with the ports in the vertical position that would make the hose installation much easier. Anyone make a similar installation and have any recommendations.