jaschrumpf

Contributing Member

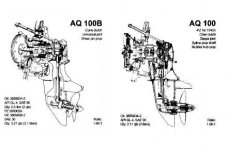

...of the rubber bellows that covers -- I think -- the universal joint at the connection just outside the transom where the outdrive connects to the engine? Is it supposed to contain the oil that's splashed on that joint?