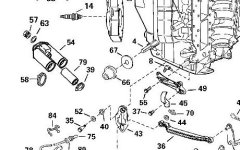

I didn’t run the engine much at all because the waterpump discharge directional piece either fell off or someone thought they needed it more than I did, guess I'm lucky I still have cowl.

Result water not peaing but pouring out also the water temp red light was on I was not in a good mode after traveling 220 miles to find out I could possibly over heat the engine.

I rigged what I could a garden hose male and a piece of hose squeezed in hope of minimizes discharge.

At retrieval I lifted the cowl and found the tube for watertemp at the cylinder head that was broken was easily fixed (maybe from not properly reinstalling cowl correctly caused this).

Main question can I continue w/ my homemade discharge tube?

Thanks TB

Result water not peaing but pouring out also the water temp red light was on I was not in a good mode after traveling 220 miles to find out I could possibly over heat the engine.

I rigged what I could a garden hose male and a piece of hose squeezed in hope of minimizes discharge.

At retrieval I lifted the cowl and found the tube for watertemp at the cylinder head that was broken was easily fixed (maybe from not properly reinstalling cowl correctly caused this).

Main question can I continue w/ my homemade discharge tube?

Thanks TB