RicardoMarine

Gold Medal Contributor

.............................

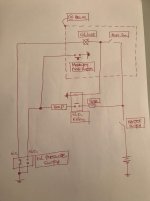

My 2006 MERC 5.7L MIE with TKS carb (2bbl) has an electric fuel pump with an "no oil pressure" switch. Works fine. The electric fuel pump's output pressure is set so that won't overcome a carb float's cut off.

I'll bet you that the 2006 Merc ECU/ECM does the same as the N/O LOP Switch does for these other systems.

Re" fresh air in engine compartment"... The bilge blower system is not intended to furnish cooling air or combustion air to the engine compartment. It is only intended to scavenge any possible gas fumes from the bottom of the bilge.

I would hope that both aspects of this are satisfied via a blower motor system.