Re: "These pins are soft...... DO NOT drive against them with any tool that is harder than an Italian Bread Stick!"

I found that on older drives, that previous owners may have driven these in or out and slightly mushroomed the outer end.

Yes Bob........, I have also seen many that were mushroomed and expanded. These can be very tough to get out.

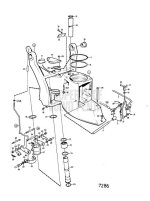

As a precaution, I swing the drive to one extreme side and carefully drive the pin out from the inside ( using said not harder than an Italian (stale?) breadstick driver)...

Go to the Italian bakery and ask for a few week-old bread sticks...... they seem to work the best.

Keep a tad bit of butter with you for the left-overs!

You should drive the pin out on that side where the pin will clear the transom shield ears when driven from the inside... swing drive to the other extreme to do the other side. Clearance is tight but it''s doable.

On occasion, you may need to drive a pin one way, and then the other a bit. This should help break up any corrosion.

Heat at the pin boss, along with a brass drift pin works well.

Always replace the plastic bushings!!!... and the pins if mushroomed. They should slide through under finger pressure alone if not mushroomed.

Agreed!

I would also grease them with water proof grease.