fpritchard

New member

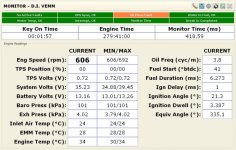

Hello all. Recently put my 89 Grady with the 225 Ficht motor in the water. First time out it ran strong with out any noticeable issues. Next time out engine fired immediately, idled around 600 rpms, and ran for about an hour or so at various rpms with no issues. Upon returning to dock entered some low water and churned up some bottom. Ran the boat for about another 30 minutes after that and didn’t have any problems. Last time out was running to reef at approx 3800 to 4200 rpms when i thought I felt a miss. I bumped up to about 4500 and it seemed to stop. Upon decreasing the throttle felt what I thought was a miss again. At that point without touching the throttle the motor began to surge from about 3000 to almost 4000 without touching the throttle. I backed it down to about 2000 and it really began running rough. As I attempted to increase throttle got a check engine light and slow mode. I shut down, waited a min or two and restarted. From this point on anything over around 2000 caused it to run rough. Throttled higher than that caused ck engine and slow mode. Limped in and got her in slip. The next day I started the motor and it started immediately idling at about 600. After about 2 minutes the idle jumped to around 1000 then began swinging between 1500 and 600.

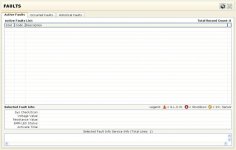

My thought initially was that I had a restriction in the emm or vapor passages which I will check. Pretty sure plugs are fouled. Leaning towards tps though based on symptoms. Any thoughts would be greatly appreciated. I would hate to pull her if I don’t have to as it is a huge PITA. Thanks all

I have cross posted in a few different forums in the hope someone has has similar issues that were resolved. One suggestion was a faulty fuel pump vapor separator.

My thought initially was that I had a restriction in the emm or vapor passages which I will check. Pretty sure plugs are fouled. Leaning towards tps though based on symptoms. Any thoughts would be greatly appreciated. I would hate to pull her if I don’t have to as it is a huge PITA. Thanks all

I have cross posted in a few different forums in the hope someone has has similar issues that were resolved. One suggestion was a faulty fuel pump vapor separator.

Last edited: