Hello all, thanks in advance for taking a look.

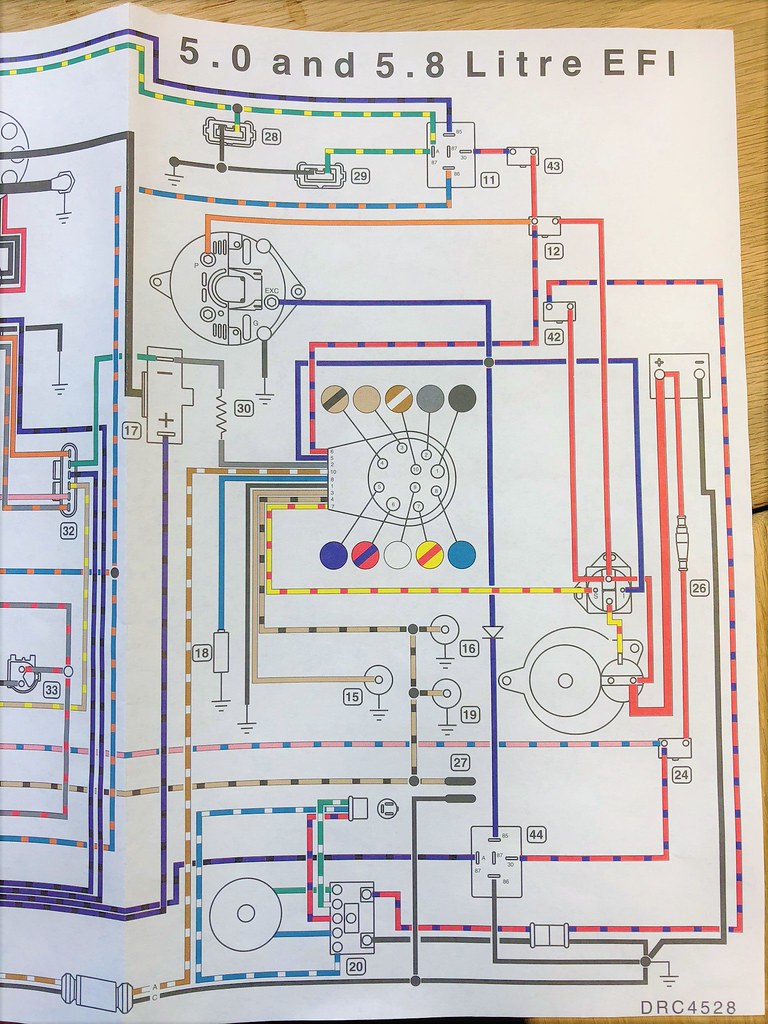

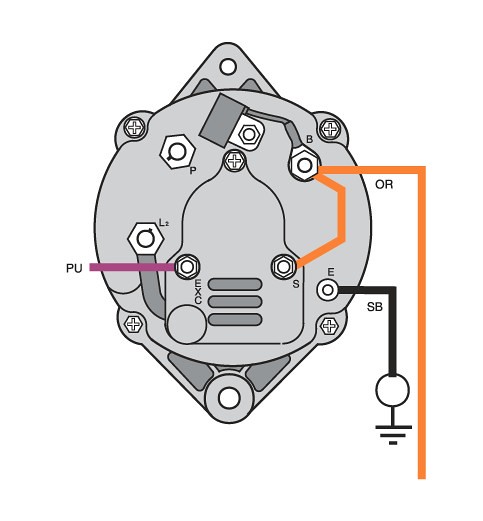

We have a Chris Craft with a 1994 omc cobra 302. We have a standard 55A alternator that keeps squealing and tearing through belts. The alternator is brand new. The old one did the same thing. We thought it had gone out, so replaced it...same issue. Engine starts fine, and alternator squeaks, making me think its overloaded. If I turn the battery switch off, engine revs up and runs perfect. When I switch back to the battery, it bogs back down and squeals. Batter is new and we've tried a couple. I figured we had a short, but the current draw from the battery when the engine is running is about 17 amps, which seems reasonable. Maybe I have a short somewhere engine side? I have pulled every fuse in the panel, no change.

Wondering if anyone has a thought on where to looks. Got a DC clamp meter coming this weekend to help out too.

Thanks!

We have a Chris Craft with a 1994 omc cobra 302. We have a standard 55A alternator that keeps squealing and tearing through belts. The alternator is brand new. The old one did the same thing. We thought it had gone out, so replaced it...same issue. Engine starts fine, and alternator squeaks, making me think its overloaded. If I turn the battery switch off, engine revs up and runs perfect. When I switch back to the battery, it bogs back down and squeals. Batter is new and we've tried a couple. I figured we had a short, but the current draw from the battery when the engine is running is about 17 amps, which seems reasonable. Maybe I have a short somewhere engine side? I have pulled every fuse in the panel, no change.

Wondering if anyone has a thought on where to looks. Got a DC clamp meter coming this weekend to help out too.

Thanks!