Chris Rohde

Regular Contributor

Hi all,

Not really a VP specific problem this time. I also posted in the fuel section, but it doesn't look like anyone's lurked in that forum for 8 or 9 months. Hoping someone here can lend some advice.

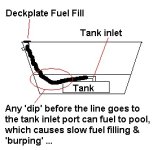

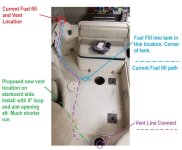

I have a problem when filling that the fuel at the pump does not shut off, and the boat pukes out a ton of fuel when filling. It's a Perko style filler, where the vent is right there at the filler opening as well. I read somewhere that these had a problem at one point in time. But this was a vague posting with no real solution. I also read, it would be good to run the vent line separate of the filler, and mount it as high and straight up as possible. I'm not sure what my options are there yet, as my filler point is already very high up.

So 2 questions;

1. Anyone know if Perko has since re-designed/fixed these somehow? Due to it's unique shape, It would be best to keep that style of filler.

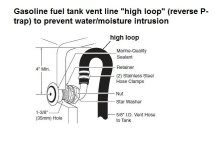

2. If I do relocate the vent higher, how much higher does it need to be to really be effective?

Thanks!!

Not really a VP specific problem this time. I also posted in the fuel section, but it doesn't look like anyone's lurked in that forum for 8 or 9 months. Hoping someone here can lend some advice.

I have a problem when filling that the fuel at the pump does not shut off, and the boat pukes out a ton of fuel when filling. It's a Perko style filler, where the vent is right there at the filler opening as well. I read somewhere that these had a problem at one point in time. But this was a vague posting with no real solution. I also read, it would be good to run the vent line separate of the filler, and mount it as high and straight up as possible. I'm not sure what my options are there yet, as my filler point is already very high up.

So 2 questions;

1. Anyone know if Perko has since re-designed/fixed these somehow? Due to it's unique shape, It would be best to keep that style of filler.

2. If I do relocate the vent higher, how much higher does it need to be to really be effective?

Thanks!!