Bait O' Eggs

Member

Having some issues with Honda 225 outboard, some background:

2003 with about 2000 hours

Exclusive salt use

Predominately tuna fishing with 50 mile runs and either trolling or stopped jigging

A year ago I broke a spark plug off in the motor and had to have a head pulled and a helicoil installed when busted plug was removed. At that time I replaced the high pressure fuel filter since it isnt easy to get to.

For the last couple years I have been losing some oil, after a couple trips I have to add a quart of 10-30 (around 24 hours). Don’t know what is up with that, adding oil is the easy fix.

I usually get a little over 2.0 mpg, this year I have been getting between 1.3 and 1.6mpg. I also have an alarm going off when at idle. It may take a few seconds or a few minutes, but at idle the alarm is like a one second buzzer with about a 1 second pause between buzzers. I have a 4 light control panel, and the green oil light and the MIL (engine light) are both on steady.

I did some poking around on the internet and figured my O2 senson had gone out since they are problematic it seems and other had similar symptoms.

In retrospect I wish I had just ordered a Honda OEM sensor, but I found some new ones from China on ebay, they meet Honda spec blah blah blah, I ordered two since they were only $17, neither of them fixed my problem. Either made of pure Chinesieum, or it wasn’t my problem???? May have to get a Honda OEM one to try.

I have read where a bad O2 sensor can make the motor run lean, dumping more fuel than it can burn lower effeciency and mileage, but also result in low power. I don’t notice any less power, but more fuel is going somewhere per mile.

When stopped at idle I see an oil slick appear behind the motor, it smells like fuel, but could be my oil that seems to be going away also????? The oil slick “seems” to be coming from prop exhaust, as you see little oil slicks appear from nowhere like they are floating to the top.

Getting to a dealer to get the code read is a big undertaking, they want the boat dropped off, I would have to take a day off from work to deliver it and pick it up, they wont just jump on it and read the code. Plus I would have to remove all my commerical fishing gear and equipment so it doesn’t get stolen from their yard.

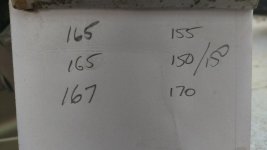

I hope to get a chance to short across the two prongs with a paperclip and read the code from the MIL light blink tonight that I found how to do on this forum today. Is there anything else I can be doing to resolve this??

2003 with about 2000 hours

Exclusive salt use

Predominately tuna fishing with 50 mile runs and either trolling or stopped jigging

A year ago I broke a spark plug off in the motor and had to have a head pulled and a helicoil installed when busted plug was removed. At that time I replaced the high pressure fuel filter since it isnt easy to get to.

For the last couple years I have been losing some oil, after a couple trips I have to add a quart of 10-30 (around 24 hours). Don’t know what is up with that, adding oil is the easy fix.

I usually get a little over 2.0 mpg, this year I have been getting between 1.3 and 1.6mpg. I also have an alarm going off when at idle. It may take a few seconds or a few minutes, but at idle the alarm is like a one second buzzer with about a 1 second pause between buzzers. I have a 4 light control panel, and the green oil light and the MIL (engine light) are both on steady.

I did some poking around on the internet and figured my O2 senson had gone out since they are problematic it seems and other had similar symptoms.

In retrospect I wish I had just ordered a Honda OEM sensor, but I found some new ones from China on ebay, they meet Honda spec blah blah blah, I ordered two since they were only $17, neither of them fixed my problem. Either made of pure Chinesieum, or it wasn’t my problem???? May have to get a Honda OEM one to try.

I have read where a bad O2 sensor can make the motor run lean, dumping more fuel than it can burn lower effeciency and mileage, but also result in low power. I don’t notice any less power, but more fuel is going somewhere per mile.

When stopped at idle I see an oil slick appear behind the motor, it smells like fuel, but could be my oil that seems to be going away also????? The oil slick “seems” to be coming from prop exhaust, as you see little oil slicks appear from nowhere like they are floating to the top.

Getting to a dealer to get the code read is a big undertaking, they want the boat dropped off, I would have to take a day off from work to deliver it and pick it up, they wont just jump on it and read the code. Plus I would have to remove all my commerical fishing gear and equipment so it doesn’t get stolen from their yard.

I hope to get a chance to short across the two prongs with a paperclip and read the code from the MIL light blink tonight that I found how to do on this forum today. Is there anything else I can be doing to resolve this??