Jupiter Dinghy

Regular Contributor

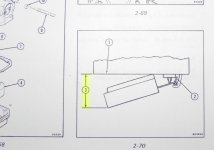

After a carb rebuilt, I used a 79 Evinrude 9.9hp and it ran good, except for one small issue: after a full throttle run, when slowing down, the engine would stall. It would start right back up and run as fine as before, until the next full throttle run and stall again when slowing down (sometimes with erratic reving prior to the stall). A user suggested adjusting the slow speed needle richer, which I did, but it didn't fix the issue. Then a couple of days ago, it got worse: after stalling, it began to show signs of difficulty restarting, with a crappy idle and would even stall after engaging forward gear. As it felt like a fuel intake issue, I decided to take the carb apart again, and I noticed the float way up, as opposed to parallel to the carb body as I read it should be. So all excited as I was, thinking I had found the cause of my problem, I bend the metal tab attaching the float to the carb slightly, so as to have it perfectly parallel to the carb, and put the thing back together after cleaning all orifices and high speed jet. Then, no start. Zero, zilch, nada. As in no fuel is able to make it to the carb tank....

So my question to the experts is this: When bending the metal tab of the float, don't we affect the way the tab is pushing down on the needle? And if so, is there a way of testing (other than by making sure we have a "parallel-to-the-carb" float)??? Because I don't see the point of a parallel float if by bending the metal tab to achieve parallelism, I shut the fuel flow off.....

Thanks as always for all the knowledgeable input!

So my question to the experts is this: When bending the metal tab of the float, don't we affect the way the tab is pushing down on the needle? And if so, is there a way of testing (other than by making sure we have a "parallel-to-the-carb" float)??? Because I don't see the point of a parallel float if by bending the metal tab to achieve parallelism, I shut the fuel flow off.....

Thanks as always for all the knowledgeable input!