Several issues possible

1. does distributor shaft "wobble" and it will be worse when engine is warm. This is due to distributor being on an angle. This could take a point gap set up when cold and cause the points to either open more or close.

2. if this issue occurs when you hit a big wave then I would think a bad or weak connection. You might have to inspect the entire engine wiring harnes to see if you have a bad connection.

3. The shift interrupter switch may be an issue. this is designed to activate when shifting out of gear only but if the switch is possibly defective or adjusted incorrectly it could activate or be activated during the conditions you describe.

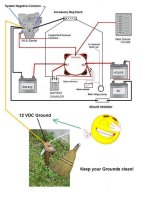

4. Point burn out would be mostly due bad ground, bad condenser, lack of grease on distributor cam lobes or to a lack of the ballast resistor. In this case the ballast resistor is a long wire in the engine wire harness (Approximately 3 feet long) and is not a normal copper wire. It has a resistance value of Approx, 2 ohms. With out it you will not only burn out the coil but also burn up the points. So if someone has rewired the coil + this could be your issue.

5. Main wire harness connector at engine (large black connector). Is this loose fitting? have you removed it and looked at the pins and sockets? if so are they clean? are the pins open? if they are closed you can carefully pry them apart to open them up a bit for better contact. Typically the large connector should have a hose clamp on it and tightened just enough to ensure good pin to socket contact.

Your "new" tach issue could be you have the set point on the back of it wrong. there should be a switch, 4, 6 ,8 and you should be on 4.