Dreadnought

New member

Folks,

I have seen many excellent answers to questions on this subject, I'm sorry to ask to repeat some things but I have not found exactly what I need. Boat is a twin 350/280 VP drive in an IMP Kansa, circa 1979.

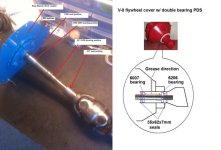

Port engine has a rattle you cannot hear at idle, but starts to get audible about 1200 rpm in neutral on the trailer, other engine is off. I am told it is the output shaft bearings (PDS I assume).

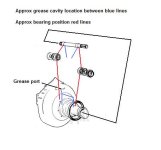

My bell housing has a capscrew on the grease port, after reading the posts, I intend to get a zerk here and grease it up, running, and listen for improvement.

I want to put about 20 min of run time on this engine at 2500 rpm or less to get a test done, once this test is done then I can pull the engine and drive and move forward with the project.

Questions:

1) Any possible guess on if I can get another 20 min run time? Is this an instant catastrophic failure, or does it increase in volume, and allow time to shut it down before ventilating the housing?

2) For bearing replacement, does the engine need to be removed on all the 280 drives, and if not how do I tell?

Please let me know if more info is needed to answer me, and thanks in advance for your help.

Larry

I have seen many excellent answers to questions on this subject, I'm sorry to ask to repeat some things but I have not found exactly what I need. Boat is a twin 350/280 VP drive in an IMP Kansa, circa 1979.

Port engine has a rattle you cannot hear at idle, but starts to get audible about 1200 rpm in neutral on the trailer, other engine is off. I am told it is the output shaft bearings (PDS I assume).

My bell housing has a capscrew on the grease port, after reading the posts, I intend to get a zerk here and grease it up, running, and listen for improvement.

I want to put about 20 min of run time on this engine at 2500 rpm or less to get a test done, once this test is done then I can pull the engine and drive and move forward with the project.

Questions:

1) Any possible guess on if I can get another 20 min run time? Is this an instant catastrophic failure, or does it increase in volume, and allow time to shut it down before ventilating the housing?

2) For bearing replacement, does the engine need to be removed on all the 280 drives, and if not how do I tell?

Please let me know if more info is needed to answer me, and thanks in advance for your help.

Larry