I have an Alpha one outdrive 1986 vintage and just pulled off the outdrive with the intention of replacing the gimbal bearing. There was a little saltwater sitting inside the gimbal bearing bellows. I was looking for a leak in the bellows and saw a smooth circular piece of stainless steel protruding through the bellows, but it doesn't seem to be leaking after I took a garden hose and shot water at the site for a leak test. Is this supposed to be part of the bellows?

The water contamination doesn't appear to be a result of a big leak, but I did find another possible cause. The upper gear housing had a broken large o-ring seal. The O-ring compresses and basicly seals around a retainer nut and the bell housing . I also noticed that the retainer nut had one piece of its 'Castle' broken off. I believe this is affecting the O-rings ability to seal out water since the O-ring isn,t backed up and completely supported. If I remove the U-joints and then replace the retainer nut, will I disturb anything in the upper gearcase housing?

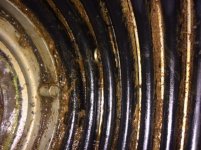

Picture of bellow attached (ring is inside, top right side).

The water contamination doesn't appear to be a result of a big leak, but I did find another possible cause. The upper gear housing had a broken large o-ring seal. The O-ring compresses and basicly seals around a retainer nut and the bell housing . I also noticed that the retainer nut had one piece of its 'Castle' broken off. I believe this is affecting the O-rings ability to seal out water since the O-ring isn,t backed up and completely supported. If I remove the U-joints and then replace the retainer nut, will I disturb anything in the upper gearcase housing?

Picture of bellow attached (ring is inside, top right side).