Well an update, got my new bearings, put the bearing box together torqued the screw to 55 lbs

while turning the bearing box and checked the rolling torque. It started rolling around 10.5 lbs of force and then rolled around 7.5 lbs, did this a few times and it was pretty much the same. The book says 8.11 lbs.

OK...... as noted earlier, you have the steel bearing box.

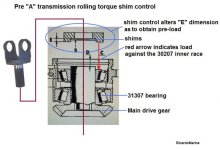

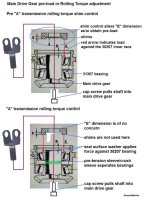

As mentioned...... the rolling torque value is shim controlled, not pre-tension sleeve controlled. (shims will be inside of the seal surface washer)

The string is to be wrapped around the OD of the BB while the universal shaft is being held firmly in the bench vice.

The scale pulls on the string, and will give you a measurement of resistance in the form of "weight".

I make it a practive to never suggest values (torque specs, timing specs, clearances, etc) ..... there is just too much room for misinterruptation, misunderstanding, etc. It's always best if the owner verifies the specs for this!!!!!!

NO Seloc or Clymers manuals...... Use ONLY OEM Volvo Penta.

I will say that 8.11 lbs of string pull resistance sounds very high.

Rick or Kim could you tell me if the rolling torque is calculated using the starting force or when it's actually rollling.

I have always been more concerned about the value once actually rolling.

Make sure that the bearings are oiled!

If it is too high I'm going to order the shims, I was going to get a 5, and 10 mm one, any thoughts on the thicknesses?

The thinner shims are of more value because you can create more combinations when mixing them with the existing shims.

Reducing the shim pack = increased bearing resistance.

Increasing the shim pack = decreased bearing resistance.

Im going to replace the steel washer as the seal surface looks good where the seal rides but the other half of washer is rusty. I did polish the seal surface and all other surfaces were good.

You can remove (polish away) up to .005" with no issues.

Just make sure that you DO NOT leave any micro-scopic spiral swirl marks! (spiral swirl marks may cause the seal lip to pull or push oil past it)

i borrowed a dial indicator to check the back lash buts that's on hold for now. Depending on what I do it will take another week to get parts.

Thanks Kilwinning.