Some history

I got this CD-12 with the purchase of a new house. The motor probably sat for 10 years since the previous owner didn't seem to know anything about it and he had the house for 10 years. My son and I have been working to restore it since august. We have replaced all the gaskets, rebuilt the carburetor, converted from the pressure tank to the fuel pump, changed the impeller, changed the gear oil (which by the way looked and smelled like dog vomit). We have it running at throttle up.

Problems 1) The engine will not run at idle speed. We can get it running when it is set just above start on the throttle handle and then taken to high throttle right a way. It will run for a little while maybe a minute and then starts to bog down. And if you go towards idle or throttle down it will start to die. 2) It is extremely hard to pull start. I am 40 years old and in good shape and I have to pull with all my might multiple times before it will start. 3) There is a hole in the lower end above the prop that looks like it is supposed to be there. It is the size of a small nail maybe 1/16" diameter and leaks gear fluid when the engine is running and for a day afterwards. 4) The carb bowl needs a new gasket and filter. I have a solution for this from vintageoutboard.com.

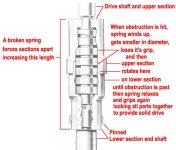

In speaking with vintageoutboard he suggested there is something binding up either in the power head or in the lower unit. So I pulled the power head off and I can turn it easily. So my thought is it is in the lower unit. The shifter was in neutral and I was turning the drive shaft is very difficult. I expect there is a problem in the low end but I am unsure how to troubleshoot it. There is a lower end on sale on Ebay for $95 and I am wondering if I should buy that. The low end of this unit is pretty banged up. Any advice is appreciated. Thanks

I got this CD-12 with the purchase of a new house. The motor probably sat for 10 years since the previous owner didn't seem to know anything about it and he had the house for 10 years. My son and I have been working to restore it since august. We have replaced all the gaskets, rebuilt the carburetor, converted from the pressure tank to the fuel pump, changed the impeller, changed the gear oil (which by the way looked and smelled like dog vomit). We have it running at throttle up.

Problems 1) The engine will not run at idle speed. We can get it running when it is set just above start on the throttle handle and then taken to high throttle right a way. It will run for a little while maybe a minute and then starts to bog down. And if you go towards idle or throttle down it will start to die. 2) It is extremely hard to pull start. I am 40 years old and in good shape and I have to pull with all my might multiple times before it will start. 3) There is a hole in the lower end above the prop that looks like it is supposed to be there. It is the size of a small nail maybe 1/16" diameter and leaks gear fluid when the engine is running and for a day afterwards. 4) The carb bowl needs a new gasket and filter. I have a solution for this from vintageoutboard.com.

In speaking with vintageoutboard he suggested there is something binding up either in the power head or in the lower unit. So I pulled the power head off and I can turn it easily. So my thought is it is in the lower unit. The shifter was in neutral and I was turning the drive shaft is very difficult. I expect there is a problem in the low end but I am unsure how to troubleshoot it. There is a lower end on sale on Ebay for $95 and I am wondering if I should buy that. The low end of this unit is pretty banged up. Any advice is appreciated. Thanks