I am building 2 408 Cu In 360 Magnum based motrs for my 27' Magnum marine sedan. THe specs are as follows:

5.9 Magnum blocks

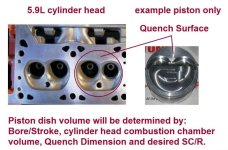

Engine Quest Iron Magnum replacement heads W 2.02 I 1.62 E valves

Icon 983 Forged step dish pistons with a 27 CC dish

Scat Cast Iron 4" stroke cranks

Scat I beam connecting rods

Hughes Engines Hydraulic roller cams 217/227 duration at .050 114 lobe separation .539/.555 lift

Edelbrock Performer RPM Air Gap intakes

Mallory Marine unilite distributors

1985 up Chrysler marine center rise exhaust manifolds / risers thru hull exhaust

Closed cooling for the blocks

Crank mounted raw water pump

I assembled my short blocks and the quench dome is .001 in the hole.

Cometic makes head gaskets in .040,.045,.051,.056, and .060 thicknesses

my compression ratio looks like this:

.040 gasket 9.406 static 8.179 dynamic

.045 gasket 9.318 static 8.056 dynamic

.051 gasket 9.215 static 7.968 dynamic

.056 gasket 9.131 static 7.897 dynamic

.060 gasket 9.065 static 7.841 dynamic

Trying to balance quench and compression ratio, Most marinas around here have 91 Octane Alchohol free fuel

5.9 Magnum blocks

Engine Quest Iron Magnum replacement heads W 2.02 I 1.62 E valves

Icon 983 Forged step dish pistons with a 27 CC dish

Scat Cast Iron 4" stroke cranks

Scat I beam connecting rods

Hughes Engines Hydraulic roller cams 217/227 duration at .050 114 lobe separation .539/.555 lift

Edelbrock Performer RPM Air Gap intakes

Mallory Marine unilite distributors

1985 up Chrysler marine center rise exhaust manifolds / risers thru hull exhaust

Closed cooling for the blocks

Crank mounted raw water pump

I assembled my short blocks and the quench dome is .001 in the hole.

Cometic makes head gaskets in .040,.045,.051,.056, and .060 thicknesses

my compression ratio looks like this:

.040 gasket 9.406 static 8.179 dynamic

.045 gasket 9.318 static 8.056 dynamic

.051 gasket 9.215 static 7.968 dynamic

.056 gasket 9.131 static 7.897 dynamic

.060 gasket 9.065 static 7.841 dynamic

Trying to balance quench and compression ratio, Most marinas around here have 91 Octane Alchohol free fuel

Last edited: