Look at the link below. The prop shaft seal is item #18 and yes, I forgot to mention the case Oring which is item #19

http://www.boats.net/parts/search/H...F100D LA/PROPELLER SHAFT PROPELLER/parts.html

In the link below is the shift shaft seal, item#24....along with it's holder, item#6..... and the holder Oring, item #25. All three of which I replace anytime I open one up.

http://www.boats.net/parts/search/H...EXTENSION CASE GEAR CASE SHIFT ROD/parts.html

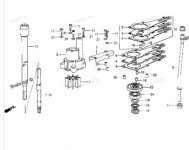

The link below depicts the pinion shaft, item #9 and water pump assembly, items 1,2 and 5.

Then there is item #3, the badly named "impeller cover". I say badly named because it sits UNDER the impeller. It is sandwiched between the two gaskets, item #4.

The cover gives the impeller a smooth metal surface to ride on but it also acts as a retainer to keep the pinion shaft held down. The area that the impeller rides on should be lightly smeared with marine grade grease during assembly for a smooth initial start up. The cover must be removed to get the pinion shaft out. Note that when the shaft is slid upward and removed, the pinion gear will likely fall into the gear case. Because this happens it is wise to have the prop shaft removed so the pinion doesn't get wedged inside and make things just that much more difficult.

Item #17 is the seal that rides the pinion shaft to keep the case sealed. The pinion shaft must be replaced if the area the seal lip contacts is worn.

Also, note items #14 and 15, collar A and collar B respectively. It is necessary that these be properly placed so that the water pump sits correctly on the "cover" and forms a tight seal. These collars are frequently installed incorrectly and cause pump leakage and efficiency problems.

http://www.boats.net/parts/search/H...F100D LA/WATER PUMP VERTICAL SHAFT/parts.html

When I do one of these, I completely disassemble and inspect all the parts of the transmission. More often than not, many parts are worn out and need to be replaced. This includes bearings and gears. These old outboards are just that, OLD. In some cases they are in fine condition due to low hours of usage. But in the majority of the ones I've had the privilege to work on, they have been relied on to power small boats and large for hundreds of hours and with little to no maintenance at that.

If you take your time and get the old girl back up to snuff, you will be rewarded with one of the most reliable and rugged outboards ever produced.