What I was alluding to was that if the LU was correct originally, then if the end play is still under 0.016, it is still OK. In other words, you may get lucky.

If it is more than that, replacing the A bearing probably changed the dimension, and then you would want to go through the checks. A dealer may be your best bet for that, as the special gauges aren't cheap, plus you need a dial indicator and mag base to take the readings. The minimum prop shaft end play is zero (but not binding); think 0.002 or so, up to 0.016. Thing is that machining is very precise these days, so you may get lucky, even after changing the A bearing, especially if you go with OEM parts. In most cases, the shimming is required because of differences in the machining of the gear case (and prop shaft housing) -- not the actual bearings or gears, which tend to be Very accurate.

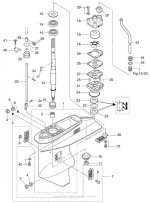

The concept is that the B gear is fixed fore and aft; if setting lash, you start by shimming the B gear to clear the gauge by the proper amount (proper depth into the case), then you shim the A gear to it, then the B gear.

If the A gear is shimmed too much, the A and B gears will bind. If not enough, it will be sloppy. Same with the B to C backlash setting.

So, if it was right originally, and now, after changing the A bearing, and there is extra end play, the A bearing is probably "thinner"... and then... if you just add C gear shims, the A gear is loose, while the C gear may bind a little. Likewise, if the new A bearing is "thicker", there won't be any prop shaft end play -- it may be binding... Either way, that would end up being noisy, and wearing the B gear pretty fast, shedding shavings into the lube, which can get expensive very fast.

BTW... When you reinstall the spring, make sure it is seated all the way down, so it can sling lube up.