quarkiegal

New member

I have a 1986 Bayliner Ciera 2450 with a Volvo Penta AQ225 and either 280 or 290 Sterndrive. We bought the boat used a few years ago and have been battling electric and transmission issues so I'm fairly familiar with manuals & repairs. Most recently, I adjusted the reversing rod on my own (with help from this forum) after getting a $3000 quote from our local boat repair.

We recently bottomed out pulling up to the dock before loading on the trailer. There was significant damage to the prop but it worked fine to get it loaded and the next time we took it out. However, when we last launched, the propeller wouldn't engage on forward or reverse. The engine was running fine and I could feel the gear shift catch when I moved it to F or R but got no movement in the water. We ended up needing help from others to manually maneuver it back onto the trailer.

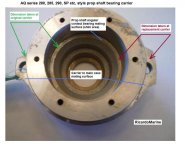

Upon further inspection I found additional damage to the housing unit behind the propeller. It looks like it was turned or twisted when the prop hit. However, I'm not certain what consequential damage I could be facing. For example, would damage like this impact the propeller shaft?

I've attached some pictures to illustrate the damage. I hope that someone with more expertise can give me some guidance.

My question is.. is this easily fixable? Is it something I could do myself? Is it something which will cost too much and, essentially, totals my boat?

Thanks for your help!

Tricia

We recently bottomed out pulling up to the dock before loading on the trailer. There was significant damage to the prop but it worked fine to get it loaded and the next time we took it out. However, when we last launched, the propeller wouldn't engage on forward or reverse. The engine was running fine and I could feel the gear shift catch when I moved it to F or R but got no movement in the water. We ended up needing help from others to manually maneuver it back onto the trailer.

Upon further inspection I found additional damage to the housing unit behind the propeller. It looks like it was turned or twisted when the prop hit. However, I'm not certain what consequential damage I could be facing. For example, would damage like this impact the propeller shaft?

I've attached some pictures to illustrate the damage. I hope that someone with more expertise can give me some guidance.

My question is.. is this easily fixable? Is it something I could do myself? Is it something which will cost too much and, essentially, totals my boat?

Thanks for your help!

Tricia