Egobbo

New member

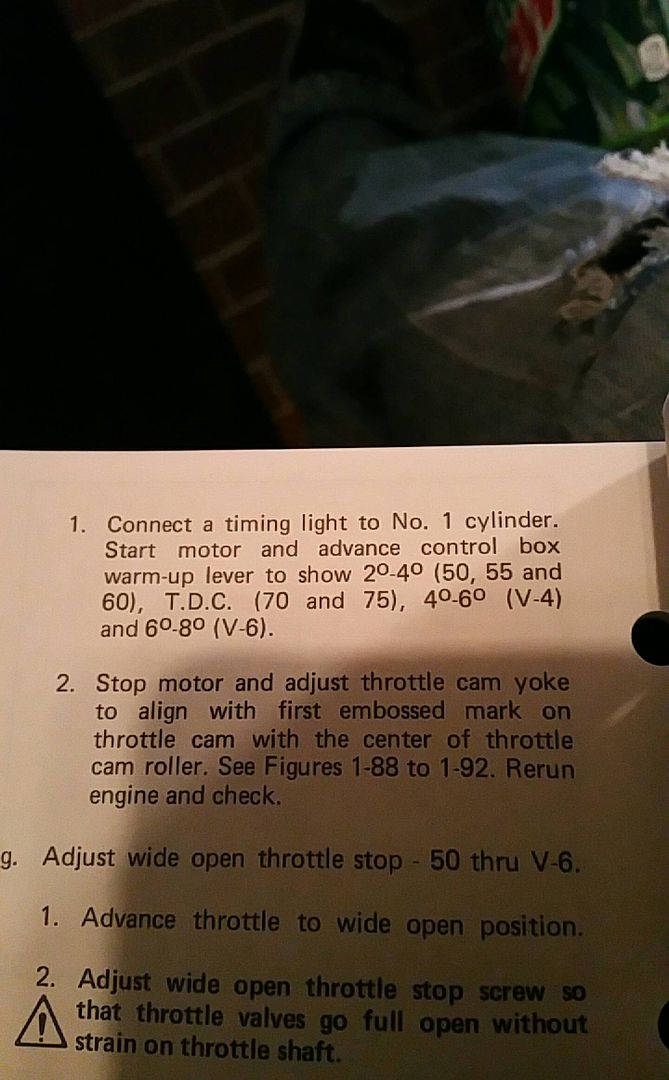

Hey guys, first time poster. been reading here alot. So i was gifted a boat, which needed a full rehab, floors stringers and transom. Finished that up, and now onto the motor. I was told that she was a good runner, by the previous owner, who is a longtime family friend. He owned it for over 20 years. Anyway, It sat for about 7 years, Ive completley gone thru the fuel system, sonic cleaned carbs, new lines, new tank etc. I still cant get this thing running right. Idles great in the water, under load it will move under its own power, till about 1/4 throttle, then bogs out and shuts off. Ive had the boat take off and get up on plane twice so far and seemed like it would stay running, but i didnt want to get too far away from the dock. Found bottom coil arcing thru case to block so i replaced it. I have the factory manual and im trying to do the link and sync. According to manual base timing should be at 4 deg. I can get it to 2deg, anything more and it starts running poorly and timing light goes haywire. Compression is good at 120 across the board. water pump, thermostat, fuel pump is all new. Carbs have been thoroughly cleaned, and lines have been replaced. Any Ideas? Im stumped...