darrylsiemer

New member

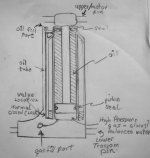

I’ve sketched up my guess (ATTACHED) of the internals of the notoriously problematic “tilt assist” lift cylinder that came standard with many 30-50 hp 1990-2005 JOHNRUDEs (part no. 0434037, list price $625.99). I’ve assumed that it’s basically just a little bottle jack with some high pressure gas (nitrogen) trapped under its piston and hydraulic oil above it. That oil is pushed into the surrounding outside chamber when the piston is raised (motor manually lifted) and the valve connecting the top of the piston's cylinder to the bottom of the latter is “open” (the lever at the motor’s passenger side pushed backwards).

Questions:

1) Is this how it’s really plumbed?

2) If “no”, how is it configured?

3) If “yes”, why wouldn’t the substitution of a 1/8” NPT shrader valve (cheap, about $3) for the plug in its bottom “fill port” fix most of the problems experienced with it? (doing so would permit a mechanic to easily replenish the nitrogen which inevitably slowly leaks past the seals of such things –it would also allow him/her to tailor the degree of “assist” provided to a particular situation.)

Although generally considered to be "unserviceable", I suspect that these units could indeed be serviced in the fashion I've suggested - there's nothing magic about gas charged shock absorbers & one tank of nitrogen (or argon) could recharge hundreds of them. The real difficulty is that no one outside of OMC seems to know how this particular gadget was built & it's been unwilling to divulge that info.

I also suspect that the reason so many actuator cables failed is that motor owners assumed that valves were "stuck" when the initial gas charge had just leaked down to the point that the motor became too heavy to manually tilt & therefore responded by hammering down its tilt assist release lever.

Questions:

1) Is this how it’s really plumbed?

2) If “no”, how is it configured?

3) If “yes”, why wouldn’t the substitution of a 1/8” NPT shrader valve (cheap, about $3) for the plug in its bottom “fill port” fix most of the problems experienced with it? (doing so would permit a mechanic to easily replenish the nitrogen which inevitably slowly leaks past the seals of such things –it would also allow him/her to tailor the degree of “assist” provided to a particular situation.)

Although generally considered to be "unserviceable", I suspect that these units could indeed be serviced in the fashion I've suggested - there's nothing magic about gas charged shock absorbers & one tank of nitrogen (or argon) could recharge hundreds of them. The real difficulty is that no one outside of OMC seems to know how this particular gadget was built & it's been unwilling to divulge that info.

I also suspect that the reason so many actuator cables failed is that motor owners assumed that valves were "stuck" when the initial gas charge had just leaked down to the point that the motor became too heavy to manually tilt & therefore responded by hammering down its tilt assist release lever.