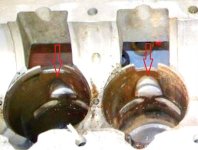

There, fixed 'em for ya! Sure doesn't look like 90hp ports to me! They are quite large.

Now, run the piston all the way down out of the cylinder and look straight thru the intake ports to the other side of the cylinder. You'll see the exhaust ports. Maybe you can get a pic of them. I expect they'll be large.

Last thing, with the piston at the bottom of its stroke, see if you can spy the power-port hole in the side of the piston. Should be there if it's a 150.

Attached is a pic of a power-ported piston for reference. Also attached is a pic of a block that has the power-port grooves machined into the cylinder bores. With the piston all the way up, you may be able to get a finger or bent piece of wire in there to feel the cylinder. If there's no groove it's gonna feel all smooth in there; the presence of the groove will be very distinct.

Now, run the piston all the way down out of the cylinder and look straight thru the intake ports to the other side of the cylinder. You'll see the exhaust ports. Maybe you can get a pic of them. I expect they'll be large.

Last thing, with the piston at the bottom of its stroke, see if you can spy the power-port hole in the side of the piston. Should be there if it's a 150.

Attached is a pic of a power-ported piston for reference. Also attached is a pic of a block that has the power-port grooves machined into the cylinder bores. With the piston all the way up, you may be able to get a finger or bent piece of wire in there to feel the cylinder. If there's no groove it's gonna feel all smooth in there; the presence of the groove will be very distinct.

https://youtu.be/Ek56gQx-D-c WATCHED

https://youtu.be/Ek56gQx-D-c WATCHED https://youtu.be/DHy-Uxumjps WATCHED

https://youtu.be/DHy-Uxumjps WATCHED WATCHED

WATCHED