xnorfolkcityblue

New member

Hey everyone. I just found this forum as i am having a problem with a 1969 9.5hp engine that i recently picked up. It has been a headache from the start.The lower unit was partly lowered. Had to remove shift rod screw and use wedges to get lower unit off. Of course the drive shaft came out of the lower unit instead of the power head but the water tube came out of the power head instead of the water pump.It was heck getting the drive shaft out of power head. A lot of blaster oil and a little improvising. I used a couple flange brackets that has a 1 inch hole in the middle and 4 holes on perimeter for 6" bolts. I used a 2" long pipe nipple attached to the bottom flange as a spacer that went around the drive shaft. I set the lower flange on a steel plate that rested across the exhaust housing while motor rested on its head. 4 holes were drilled in the plate to match the flange holes. Bolts were ran up through plate, then bottom flange, then 2 nuts on each bolt tightened against themselves to secure blots to flange. Then i put a 1" long nut on the end of the bolts and set the upper flange on the 4 bolts. I then used 2 large cable clamps that would fit tight around the shaft just on top of the upper flange. I tightened the clamps as tight as i could to the shaft. I put a threaded bolt in the gap between the shaft and clamp as the first try the clamp split. The u bolt part was ok. Then i just started turning the long nuts against the upper flange which in turn pushed up against the u bolts. You have to rotate on all nuts fairly evenly. It was like a spreader. Periodically i would rap on the end of the shaft with a brass hammer while under tension. Patience with a couple beers and it finally popped out.

Sorry, i got off on a tangent there but maybe this will help someone. I did a lot of searching but did not find this solution. So with my current problem i did a lot of searching and could find nothing so that is why i am here.

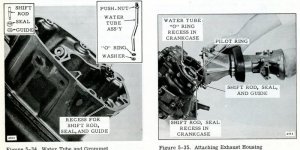

Does anyone know how to get the water tube back into the power head? I can't even find the hole or grommet. I really don't want to pull the power head off and if i must am i correct to assume that the outer covers must be removed to access to power head to exhaust mounting bolts? Is there a picture some where or a diagram that actually shows the location in the power head where the water tube goes? I even pulled out the plate in the lower exhaust housing where the water tube and shift rod o-ring and boot are to give me more visibility up the housing but i can,t make out the hole location. Any help would be greatly appreciated. Thanks.

I should mention i replaced all the seals, bushings, and o-rings, that i could get in the gear box along with a new impeller kit including the housing, and shift rod bushing and seal. The motor also will run.

Sorry, i got off on a tangent there but maybe this will help someone. I did a lot of searching but did not find this solution. So with my current problem i did a lot of searching and could find nothing so that is why i am here.

Does anyone know how to get the water tube back into the power head? I can't even find the hole or grommet. I really don't want to pull the power head off and if i must am i correct to assume that the outer covers must be removed to access to power head to exhaust mounting bolts? Is there a picture some where or a diagram that actually shows the location in the power head where the water tube goes? I even pulled out the plate in the lower exhaust housing where the water tube and shift rod o-ring and boot are to give me more visibility up the housing but i can,t make out the hole location. Any help would be greatly appreciated. Thanks.

I should mention i replaced all the seals, bushings, and o-rings, that i could get in the gear box along with a new impeller kit including the housing, and shift rod bushing and seal. The motor also will run.

Last edited: