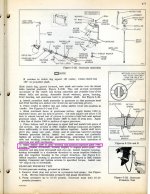

Hello , I am putting new seals in the gearcase and replacing

the impeller and impeller housing in my '73 evinrude.

In another forum a guy said to use omc/brp gasket sealant for the

outside diameter of the seals as I replace them and to use between the impeller plate

and gearcase but not between the impeller housing and plate.

He also said I could use permatex sealant that comes in a can with a

brush attached to the lid but not the exact type.

If this is true can anyone tell me if this is Permatex High-Tack gasket sealant #80062.

Thanks for any replys.

the impeller and impeller housing in my '73 evinrude.

In another forum a guy said to use omc/brp gasket sealant for the

outside diameter of the seals as I replace them and to use between the impeller plate

and gearcase but not between the impeller housing and plate.

He also said I could use permatex sealant that comes in a can with a

brush attached to the lid but not the exact type.

If this is true can anyone tell me if this is Permatex High-Tack gasket sealant #80062.

Thanks for any replys.